Laïta is a cooperative company

France's fourth-largest dairy processor, Laïta is a cooperative subsidiary of the Even group, whose mission is to make sustainable use of the milk production (1.4 billion litres by 2023) of 2,280 farms in the Greater West of France.

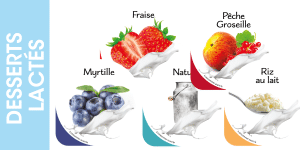

Its diversified dairy expertise enables it to offer a wide range of products, divided into four main families

- consumer products,

- dairy ingredients

- health nutrition products

- and feeding for young mammals

marketed in over 110 countries.

Its flagship brand, Paysan Breton, has a very strong reputation in France and has an international reach.

Initiated in 2015, its CSR initiative, Passion du Lait®, engages all its driving forces, including its 3,130 employees, in an ambitious progress initiative in response to societal expectations.

Discover LaÏTA

"I like PACKINOV's approach to design. Their Design Office is accessible. That's the strength of French manufacturers - they know how to design bespoke, more flexible machines."

says Jean FLOCH, Project Manager in LAITA's Technical Department

with the acquisition of a second packaging line

Laïta recently placed its trust in PACKINOV, a French manufacturer, for the second time by investing in a new bucket packaging line.

This machine will be used to package thick, liquid fresh cream in large containers.

These 1kg, 5kg and 10kg buckets are designed for manufacturers who use fresh cream in their recipes for ready meals and pizzas.

the choice of excellence for Laïta

Since 2019, Laïta has had a PACKINOV bucket line in place at its Créhen site (22) where they package spreadable cheese in 2kg, 5kg and 10kg containers.

But with liquid and thick fresh creams and growing volumes, a second packaging line was needed, on a second site.

The packaging had to meet a number of key requirements.

- The quality and precision of the dosage This machine had to accurately dose two qualities of fresh cream: thick fresh cream and liquid fresh cream. Managing this difference in viscosity is complex and required advanced dosing technology that remained precise and constant.

- The compactness of the machine The production site is restricted and the layout has to be at right angles. The machine had to have a corner transmission to fit perfectly into its environment and optimise peripheral movement of operators. Only a high-performance, adaptable standard platform could meet these requirements.

- Finally, the ergonomics of the machine: The packaging process was partly manual. Dosing was automatic, but clipping was done with a mallet. These repetitive movements were causing RSI among the operators, a problem that the company wanted to resolve quickly. Thought also had to be given to the ease with which formats could be changed, and to the weight of the various tools. For the operators, it was essential that these format changes were simple and quick, and that the components were as light as possible.

PACKINOV was chosen from among five renowned suppliers thanks to the quality of its proposal and the commitment of its teams to this project.

and team flexibility

The cooperation between Laïta and Packinov is not limited solely to the commercial transaction.

"We appreciated how well PACKINOV listened to us," says Jean FLOCH, Project Manager in Laïta's Technical Department. "They were very interested in the specifications, which are particularly extensive for us. Some suppliers don't read them, which leads to misunderstandings and wastes time. I appreciated the fact that they took it into account.

Mr FLOCH also adds: "I like PACKINOV's approach to design. Their Design Office is accessible. That's the strength of French manufacturers: they know how to design bespoke, more flexible machines.

This fruitful collaboration has led to a renewed partnership and increased confidence between the two companies in the design and manufacture of a high-quality packaging machine in France.

100% French design and manufacture

All our semi-automatic and automatic machines are designed and manufactured in France by our in-house Design Office, at our production site in Beynost in the Ain department, in the heart of the Auvergne-Rhône-Alpes region. More than just a sales argument, at PACKINOV, 100% French manufacturing is a reality and almost an obsession!

And our objectives are clear: to reach 100% of PACKINOV subcontracting partners in France, so that we can play an active role in the national revival and momentum.

Today, our results are already very positive, with over 98% from our partners based in France, including 73% in the Auvergne Rhône Alpes region and 19% in the Ain. And the others are all European!