PACKINOV testing laboratory

Serving your industrial needs

At PACKINOV, sealing is not a secondary stage: it's the ultimate guarantee that your product will reach the consumer intact, tasty and safe.

Our engineers and technicians, who have specialised for over twenty years in the technologies of weight dosage and heat sealhave developed unique expertise in adapting, making reliable and optimising each combination jar / lid.

This commitment to quality is demonstrated at the heart of our Beynost site, in a sealing laboratory fully equipped and managed by our in-house teams.

This is where your samples are tested and the optimum sealing parameters are defined for your jar and lid:

- Check that your jar and lid are compatible

- Peelability assessment

- Leak diagnosis of your sealed jar

- Determining optimum sealing parameters

- Proposal for alternative lidding materials

PACKINOV test modules

The tests are carried out using a set of equipment adapted to sealability and compatibility materials.

We use a heat sealer adjustable up to 300°C, with interchangeable settings and heads to suit the formats tested.

A generator and a induction head are also available for lids that require a special sealing technology. induction sealing.

For the mechanical assessment of seals, a traction bench capable of exerting a force of up to 40 N is used to measure the resistance to tearing.

Verification of waterproofing is ensured by a hypobaric chamber down to -1.0 barsimulating extreme transport and storage conditions.

Finally, a dry heat oven is used to test the behaviour of samples subjected to high temperatures, as part of the ageing or thermal stability tests.

Why entrust your tests to PACKINOV?

Multi-market expertise

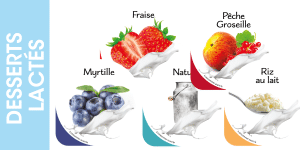

Our methodologies cover the complex constraints of the food industry (pasteurisation, acid products), cosmetics (oily and perfumed formulas) and pharmaceuticals (GMP protocols, documentary validation).

Productivity and profitability

Controlled sealing reduces logistical returns, downgraded products and material losses.

Your machine parameters are optimised to limit your energy consumption and boost productivity.

Guaranteed responsiveness

The laboratory is located on our production site.

Our team manages the test schedule to get you answers quickly and meet your marketing deadlines.

Global offer

If the test involves adjusting your machine settings, our automation specialists will come on site to integrate the parameters validated in the laboratory.

Each piece of equipment is metrologically checked according to a strict schedule;

your results are therefore reliable and reproducible.

Manufacture

100% French

Since 1997, PACKINOV designs and manufactures rotary machines and automatic packaging lines adapted to all products in rigid containers in Beynost (01).

From the outset, this company has opted for the 100% MADE IN FRANCE.

Innovative, top-of-the-range French manufacturer, PACKINOV is present in France and abroad and supports its customers at every stage of their project, in a spirit of partnership. global packaging solution with machines but also pots, the lids and many associated services.

How your trial runs

We are launching a test campaign based on samples of jars and lids that you provide.

Around thirty pots are generally needed to ensure that the tests are representative.

At the end of these tests, we analyse the results obtained and summarise them in a detailed test report, including our technical conclusion.

If the tests carried out with your seal are not conclusive, we can also offer you an alternative solution more suited to your needs.

This service is generally carried out over a day and a half for each pair of pot/opercule materials.