RMD Eco² conditioner

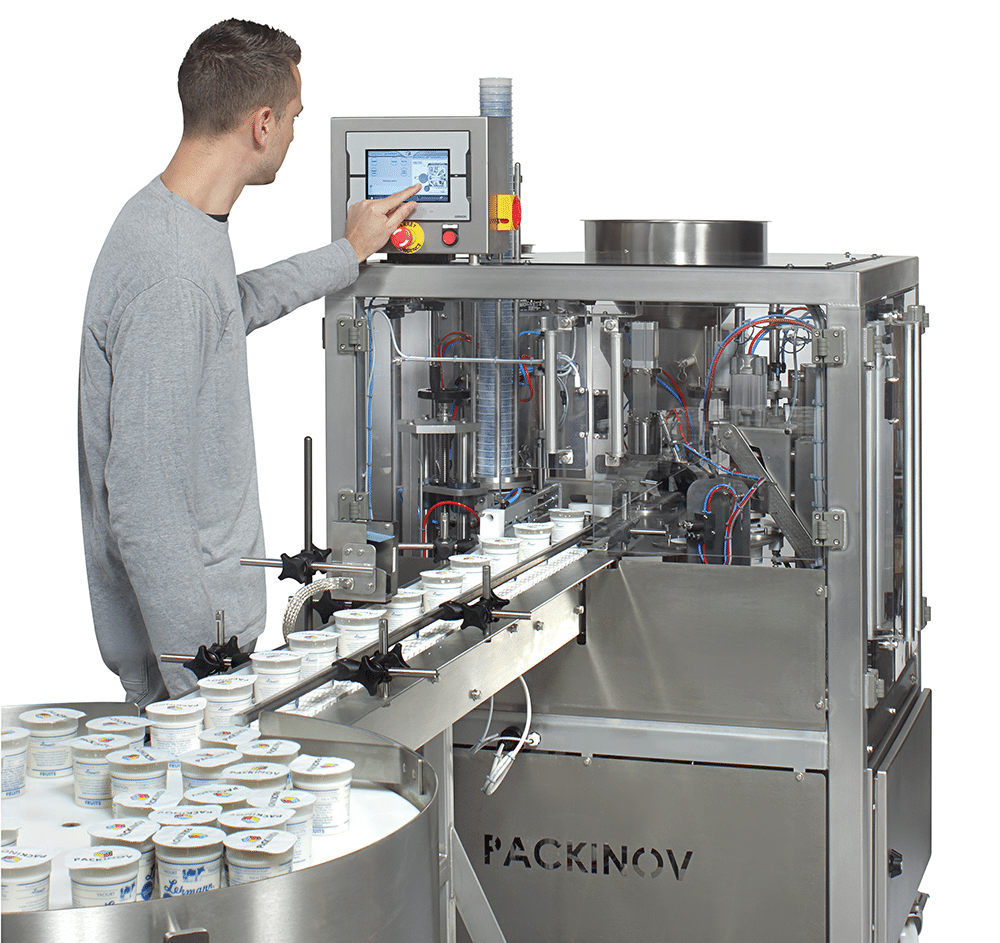

RMD² Eco yoghurt filling machine - High-performance and ULTRA-COMPACT

- Adapted productivity: 2000 pots/hour

- High dosing accuracy

- Modularity, scalability, multi-formats

- Hygienic, easy to clean

- Suitable for depilable containers of different sizes

- Possibility of two layers (honey, caramel, coulis, jam, chestnut cream...)

- Semi-automatic feeder as standard

- Optimum footprint, quick format changeover

- AGILOR, AGRILISMAT and ACTIMAT financing

Benefit from a HIGH-PERFORMANCE, ultra-compact solution

With more than 1500 machines sold worldwidethe filling machines PACKINOV have proven their worth in a wide range of fields, from from ultra-fresh dairy products to sauces, spices, honey, spreads and many other preparations, with or without pieces.

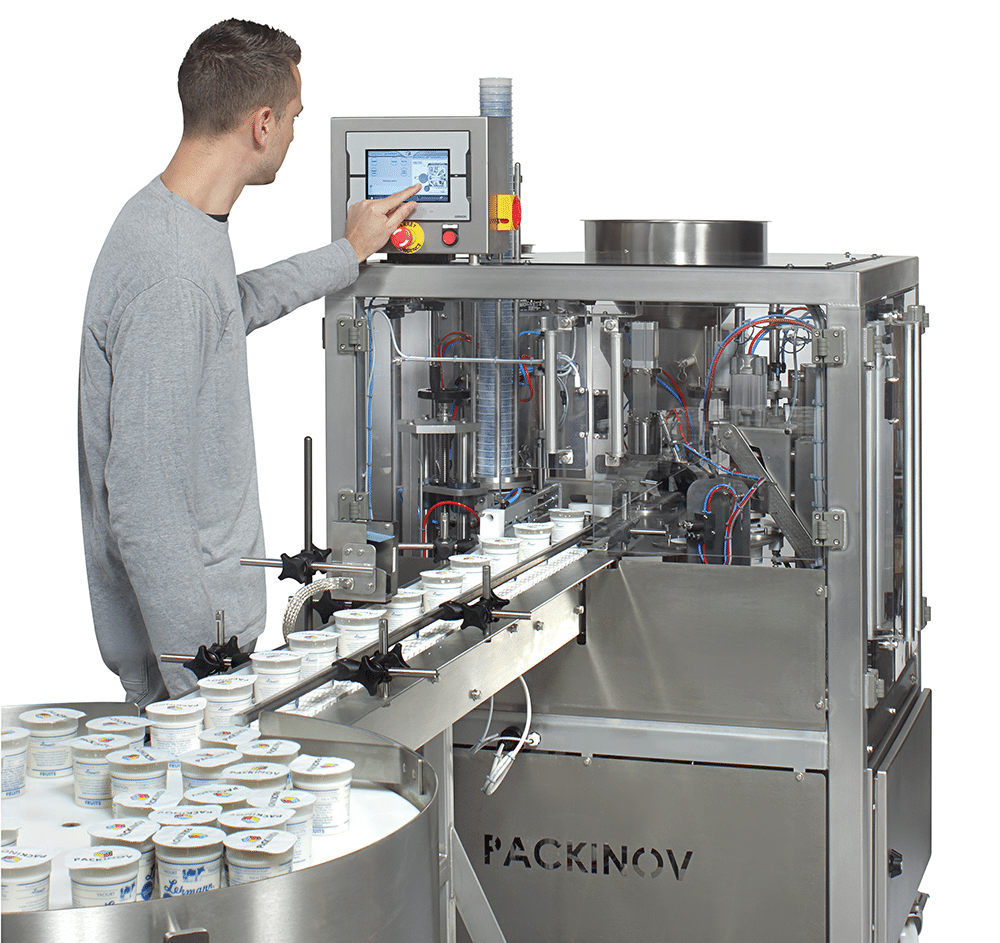

La RMD Eco² packaging machine is a high-performance machine that can achieve speeds of up to 2,000 pots per hour. It guarantees respectful handling of your products and meets your quality requirements. Entirely hard-coated and complies with current standards, its agri-food design ensures you can produce in complete safety. It's designed for you help maximise your productivity without compromising the quality of your products.

Over and above its performance, the RMD Eco² packaging machine is also incredibly easy to use. 100% automaticThis machine, which is resolutely ergonomic, limits the repetitive movements of operators and thus avoids the risk of RSI. This machine has been designed, developed and made in France, a guarantee of quality and reliability.

One of the main advantages of RMD Eco² packaging machine is its versatility. It's scalable, so you can develop your business by expanding your range to meet growing demand. Whatever your production needs, this packaging machine is designed to adapt easily.

It is an invaluable asset for success in short circuits. You can maximise your profitability and meet growing demand by offering quality products. Thanks to its performance and its versatilitythis packaging machine can help you achieve your business objectives by guaranteeing customer satisfaction.

La RMD Eco² packaging machine is a wise investment for any company looking to optimise its production and guarantee its quality standards. Its performance, ease of use and versatility make it ideal for meeting the challenges of modern industry.

efficient

pots/hour

manufacturing

French

- productivity

The RMD Eco² filling machine reaches a speed of 2,000 pots/hourWe're here to help you develop your automatic packaging business in unstackable containers, cardboard or plastic jars, and gain market share in short distribution channels.

- simplicity

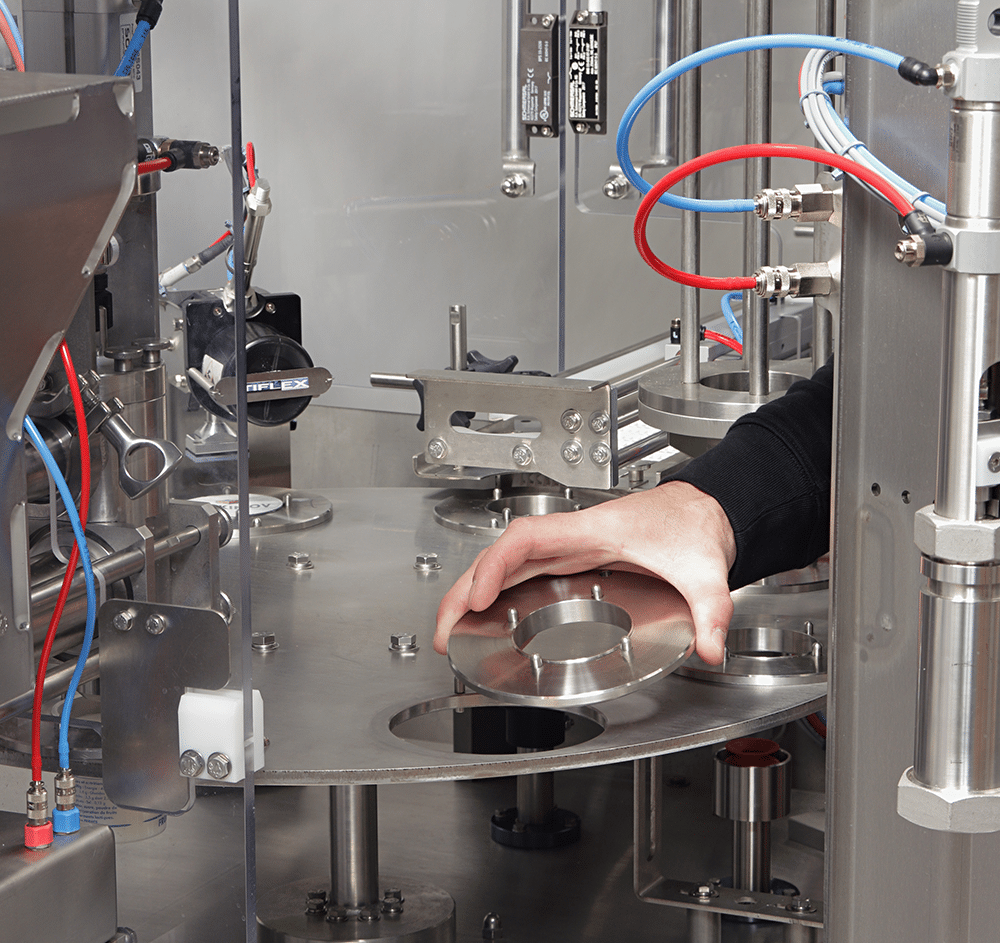

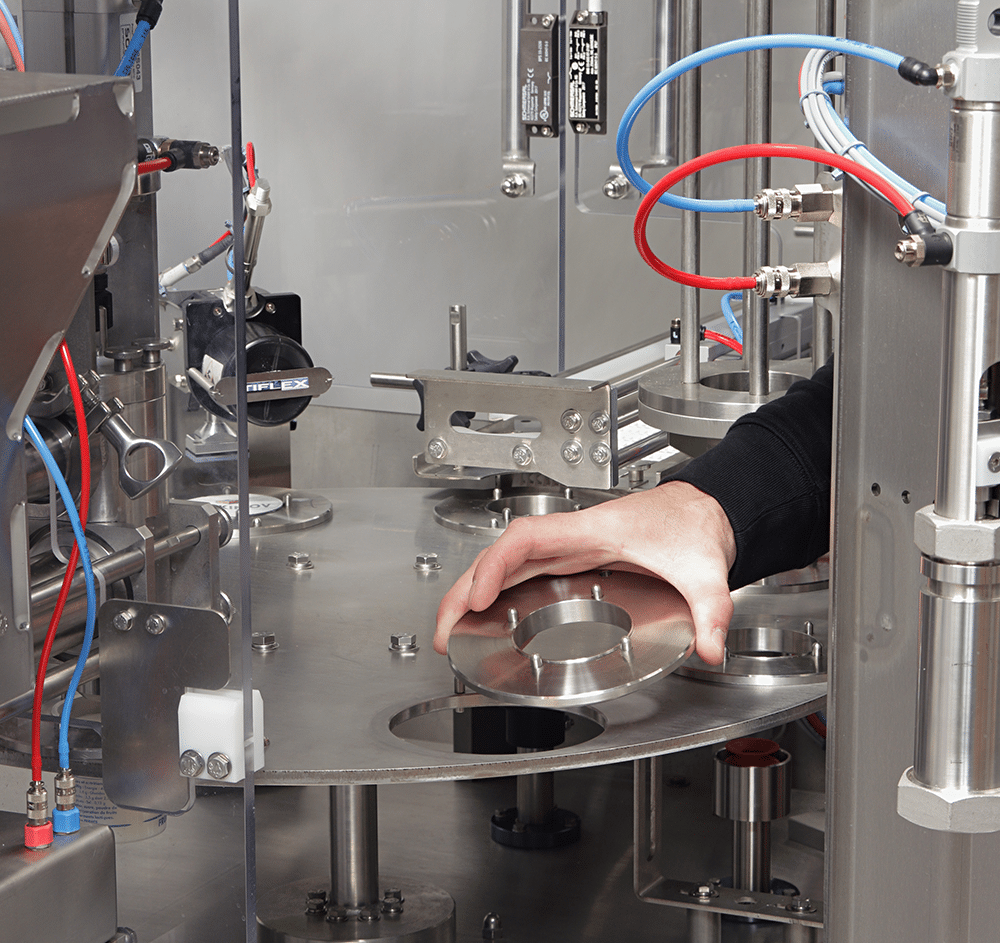

La RMD Eco² conditioner has been developed by our design office to meet the constraints and expectations of SMEs. 100% automaticIt is very easy to use, with quick format changes and no tools required.

- flexibility

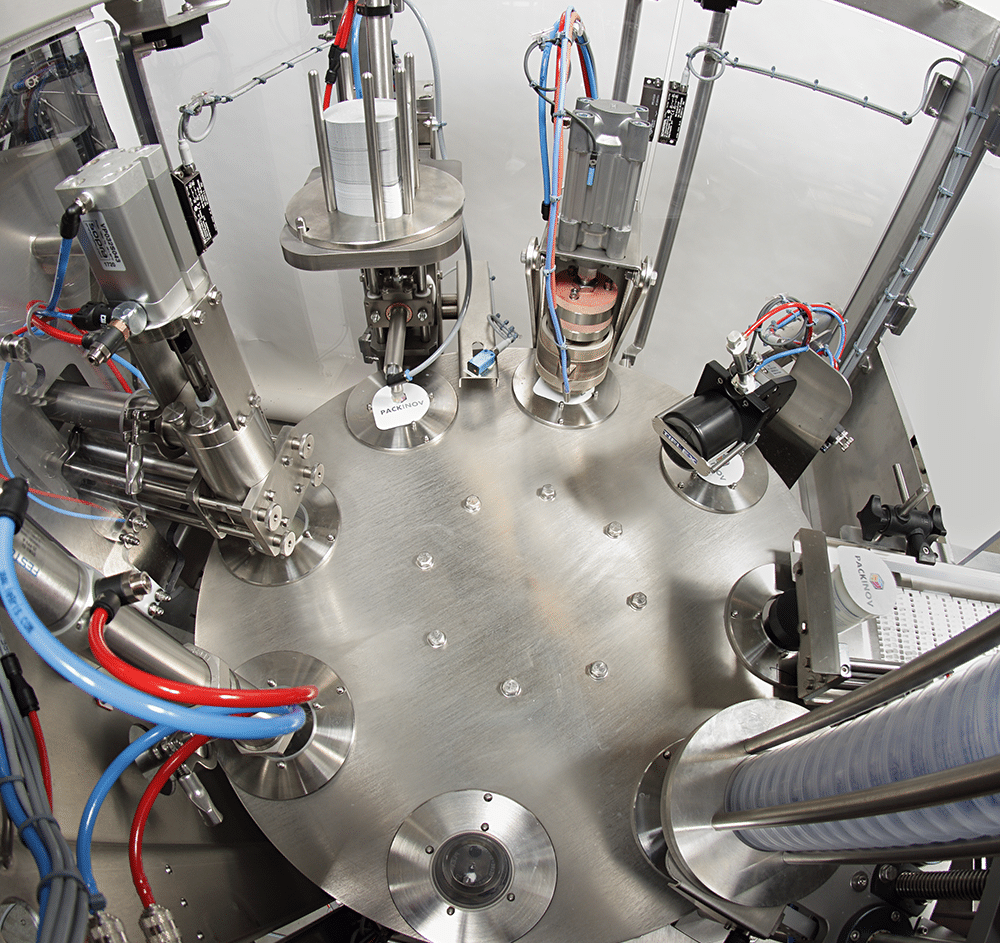

La RMD Eco² packaging machine is multi-format. It adapts perfectly to all unstackable containers from 20g to 500g, in plastic and/or cardboard, for packaging a wide range of products, including two-layer products.

- dosing precision

The PACKINOV dosing systems are renowned for their high level of dosing precision and consistency.. Indispensable for making your production more reliable, reducing tolerance margins and making significant savings on raw materials.

- ergonomics

La The RMD Eco² filling machine is ergonomic. Its footprint is optimised. 100% automatic, this filling machine is suitable for one-man operation.

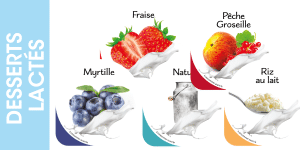

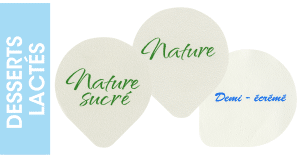

ADAPTED TO YOUR PRODUCTS

Cottage cheese

Fresh cream

Yoghurts

COMPOST

grout

fruit puree

jam

PAINTS

LASURES

COLOURANTS

CHEMICAL PRODUCTS

sauces

mayonnaise

ketchup

COATING

FERTILISERS

SAND

SPICES

TEAS

SEL

condiments

Manufacture

100% French

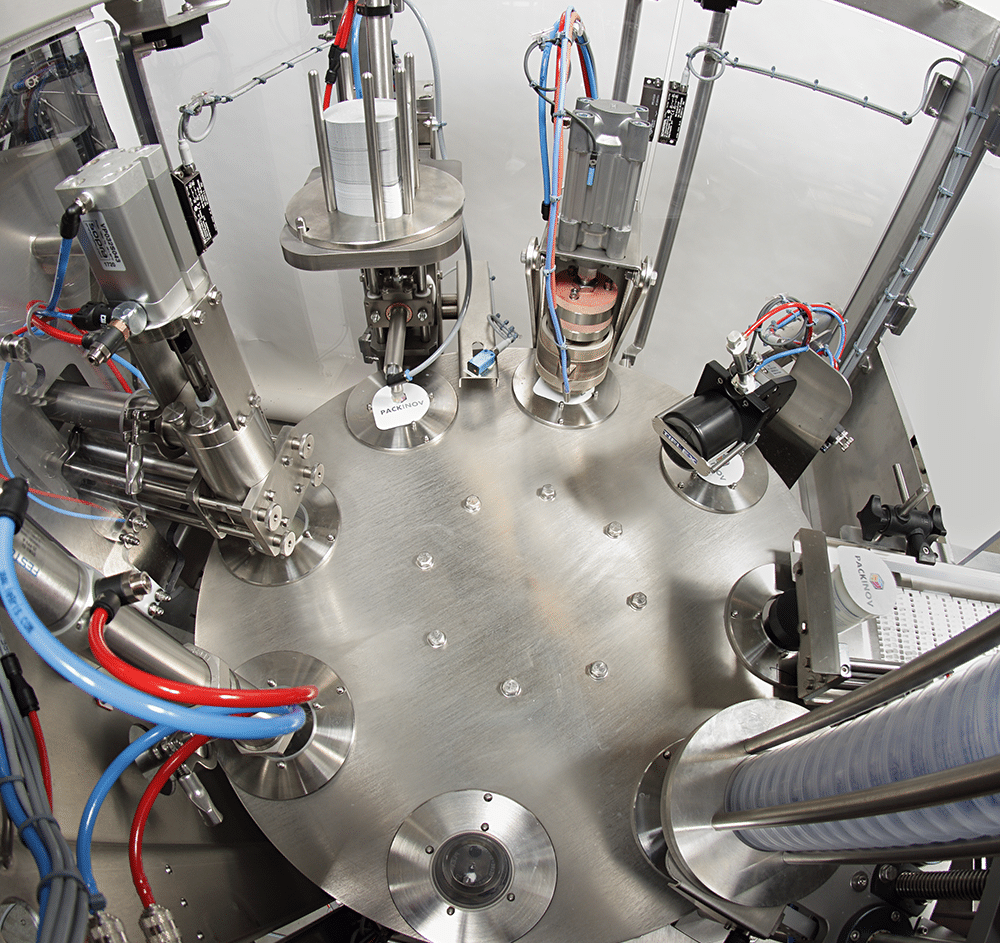

Since 1997, PACKINOV designs and manufactures rotary machines and automatic packaging lines adapted to all products in rigid containers in Beynost (01).

From the outset, this company has opted for the 100% MADE IN FRANCE.

Innovative, top-of-the-range French manufacturer, PACKINOV is present in France and abroad and supports its customers at every stage of their project, in a spirit of partnership. global packaging solution with machines but also pots, the lids and many associated services.

In stock

To try it is to adopt it

Multi-container

2000 pots/hour

THE RMD ECO² FILLING MACHINE

With a production capacity up to 2000 pots/hthe RMD Eco² conditioner allie performance and reliable. It allows you to respond quickly and calmly to the growing demand from your customers while maintaining consistent quality.

La RMD Eco² conditioner is entirely automatic. Only one person is needed to operate it, so you can optimise your teams.

La The RMD Eco² packaging machine is modular and versatilecapable of handling jars from 20g to 500g.

You can use it for two-layer dosing with products such as honey, caramel, coulis, jam, milk jam and chestnut purée...

The dosing units can also be used in semi-automatic mode for ancillary production, such as bottles of milk or yoghurt for drinking.

Ultra-compact, designed and built to comply with European Machinery Directive 2006/42/EC, in food-grade stainless steel, it meets your quality requirements, guaranteeing you enhanced safety.

La RMD Eco² conditioner proudly displays its 100% French manufacture.

It is the result of the work of a skilled and passionate team.

Finally, take advantage of the opportunity to finance your investment with a lease, or an AGILOR, AGRILISMAT or ACTIMAT loan.

Designed for

Large containers

Beverage cartons

Plastic pots

The RMD Eco² filling machine speeds up your production

and help you increase your profits by accessing short distribution channels.

Benefits of the RMD Eco² filling machine

- High productivity: 2000 pots/h

- Dosing accuracy

- Modularity, scalability, multi-format packaging machine

- Flexible, suitable for depilable containers of different volumes

- Possibility of two layers (honey, caramel, coulis, jam, milk jam, chestnut cream...)

- Semi-automatic feeder as standard

- Optimum footprint

- Easy to use, quick format changeover

- Easy to clean

- All stainless steel for foodstuffs, 100% made in France

- Ideal for short distribution channels and direct sales

- Take advantage of Lease-to-Own financing

Watch videos of the rmd Eco² CONDITIONING MACHINE

Reading list

1:05

RMD Eco² conditioner suitable for :

to the RMD Eco² filling machine

After-sales services

PACKINOV's after-sales service is at your side to maintain, repair and upgrade your machine, filler or dispenser.

You can also consult our after-sales guides for routine maintenance of your machine.

FUNDING ASSISTANCE

PACKINOV can help you with the administrative procedures involved in financing your machine.

Our machines are eligible for AGILOR, AGRILISMAT and ACTIMAT financing, and can be leased.

RENTAL

Keep all the flexibility you need to get your business off the ground.

Our machines are available for hire to enable you to launch your new products quickly and help your business grow.

Maintenance

PACKINOV's teams carry out annual maintenance on your machine and replace wearing parts to ensure that your filling machine operates at optimum efficiency and that your production continues uninterrupted.

Manufacture

100% French

All our machines are developed and manufactured in France.

Discover our production site in pictures.

our in-house test laboratory

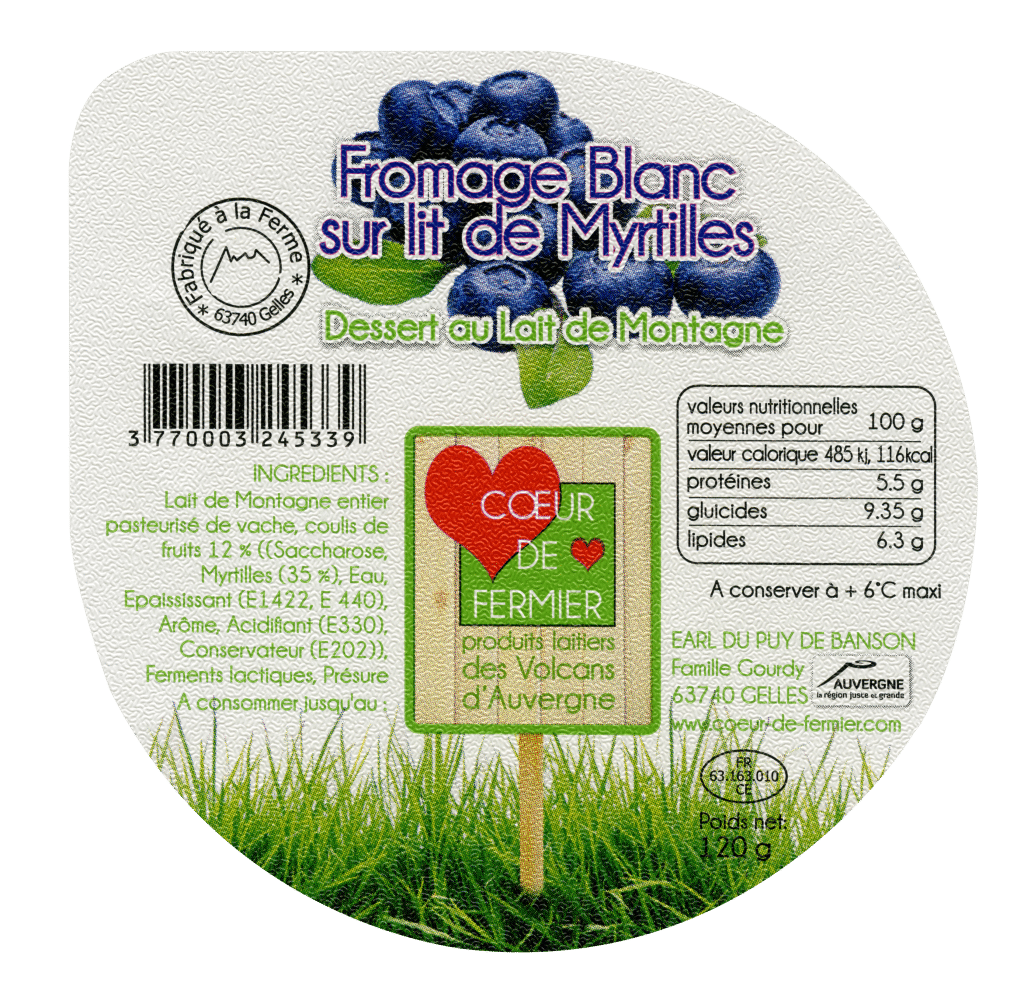

PACKINOV has its own production site in France, a quality testing laboratory.

La pot ⇔ lid compatibility can be tested therewhatever your container and its material, to ensure that perfect sealing, hold and peelability of the liner in your heat-sealing and production conditions.

Give us your pots and we'll carry out compatibility tests in our in-house laboratory!

They trust us