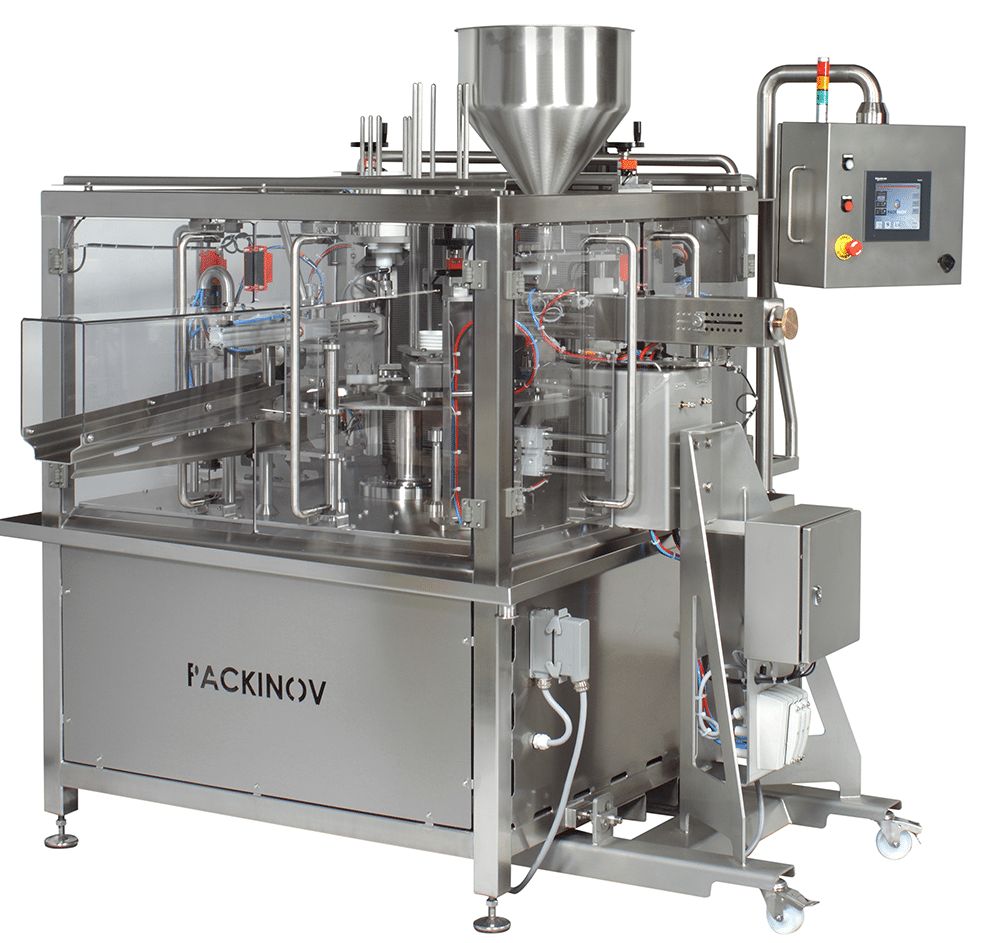

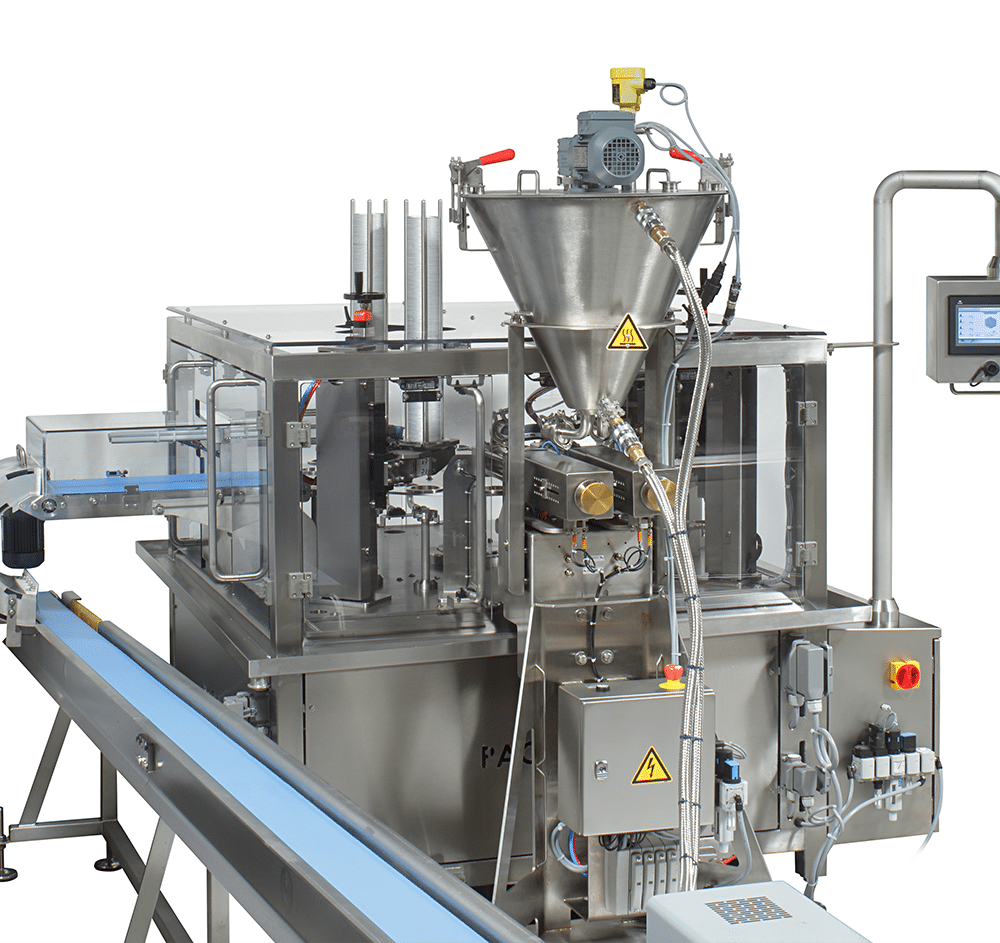

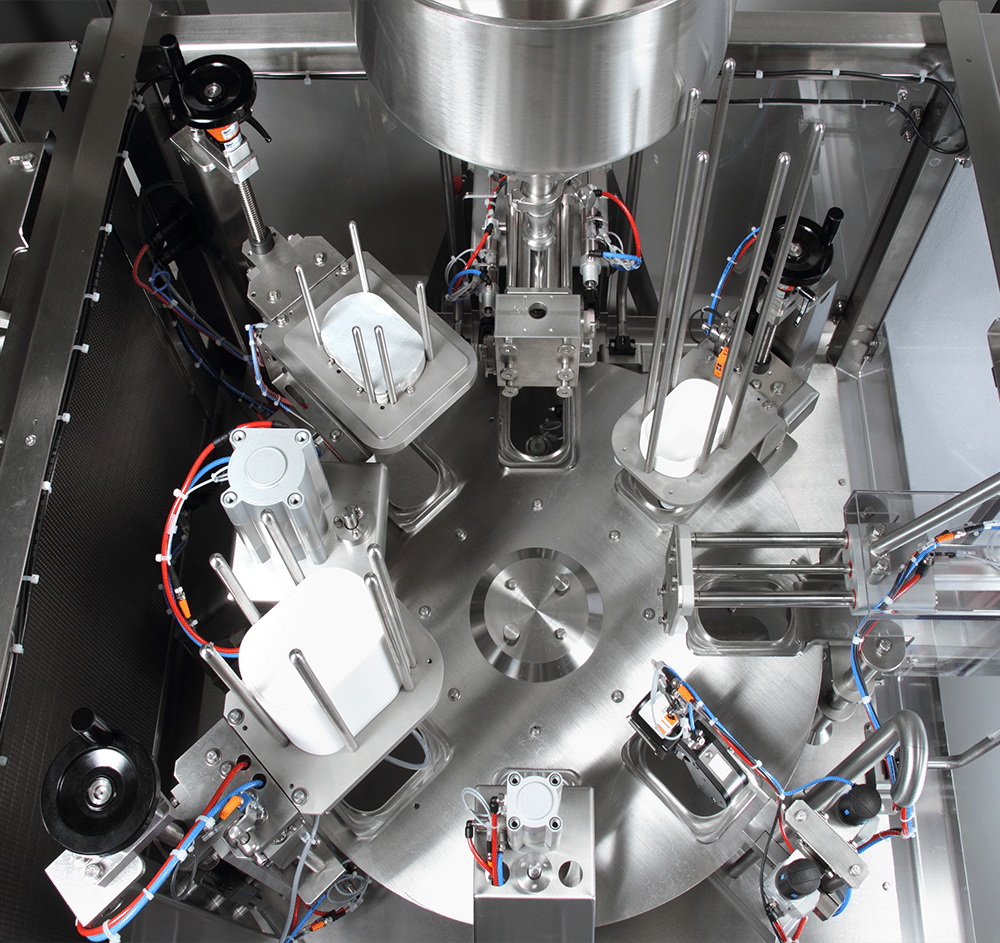

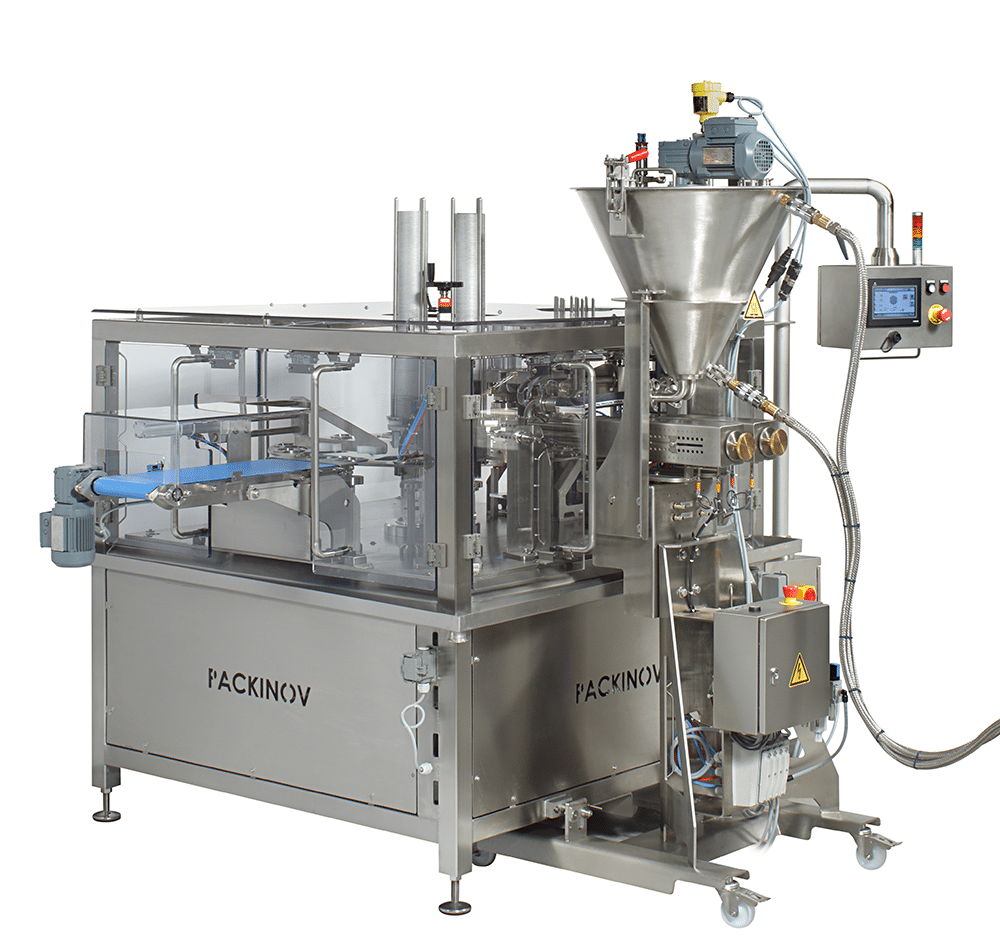

rmd 844 packaging machine

RMD 844 multi-format packaging machine

- Very high productivity: up to 8,000 pots/hour

- High dosing accuracy

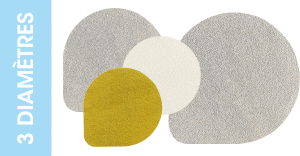

- Modularity, multi-format packaging machine

- Flexible, suitable for depilable containers of different volumes

- Easy to use, quick format changeover

- Optimised design and ergonomics to meet your requirements

- Easy to clean

- All stainless steel for foodstuffs, 100% made in France

Benefit from an ultra-compact solution

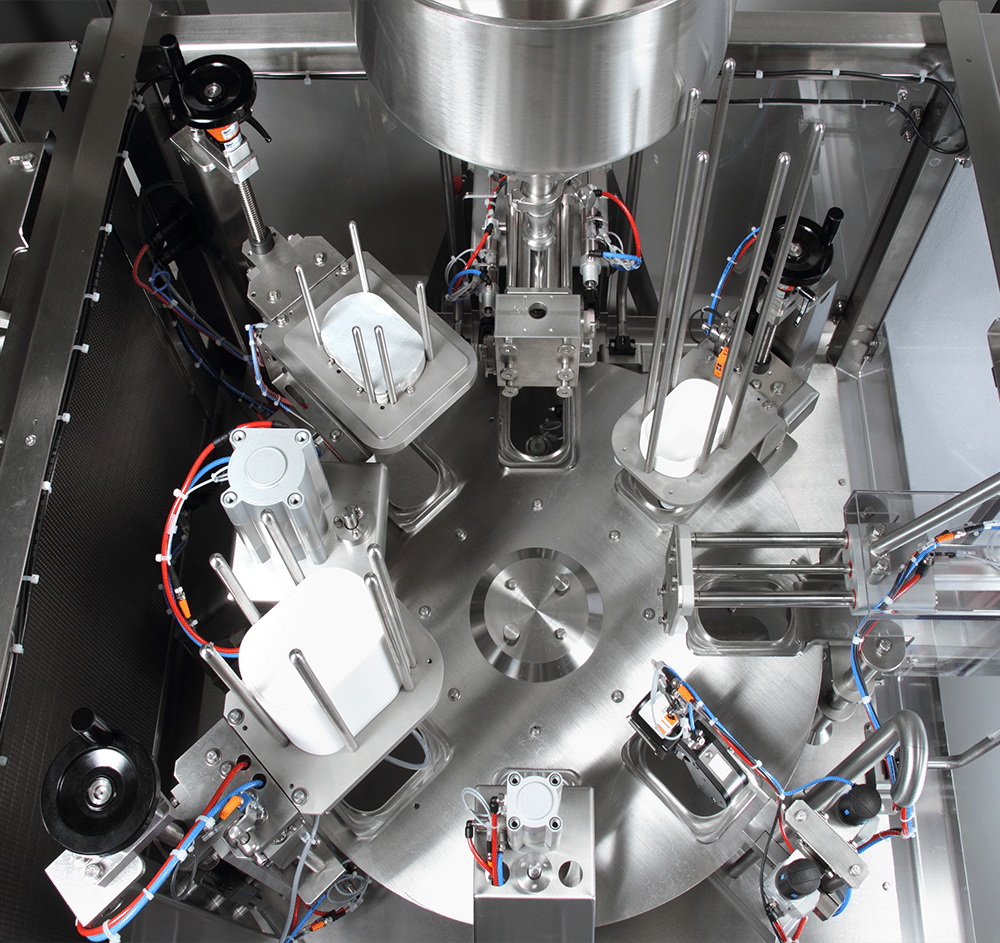

La PACKINOV RMD 844 packaging machinedesigned specifically for packaging removable potscombines technological innovation and ease of use, making it a real ally in optimising your production.

La packaging machine RMD 844, designed and manufactured in France, offers unprecedented flexibility. Whatever your products - liquids, pastes or solids - This machine is capable of accurately filling them into a variety of depilatable containers. Whether you're using pots, bowls, trays or cups, the RMD 844 adapts to all your needs. It is capable of meeting the requirements of a semi-industrial or industrial productionThis makes it an ideal choice for diversifying your offer and meeting your customers' specific requirements.

But the real strength of packaging machine RMD 844 lies in its ease of use. Thanks to its automatic packagingIt also greatly simplifies your production process. Even when changing containers, the operation is quick and easy. You can switch from one format to another in the blink of an eye. This operational flexibility represents a considerable time saving and a significant increase in your productivity.

Beyond its practicality, the packaging machine RMD 844 is also synonymous with performance. It packages your products with a exemplary precision and reliabilityThis guarantees consistent quality. Whether you're working with delicate liquids, viscous pastes or fragile solids, the RMD 844 is designed to meet your specific needs. It ensures packaging that respects your products, preserves their quality and ensures optimum customer satisfaction.

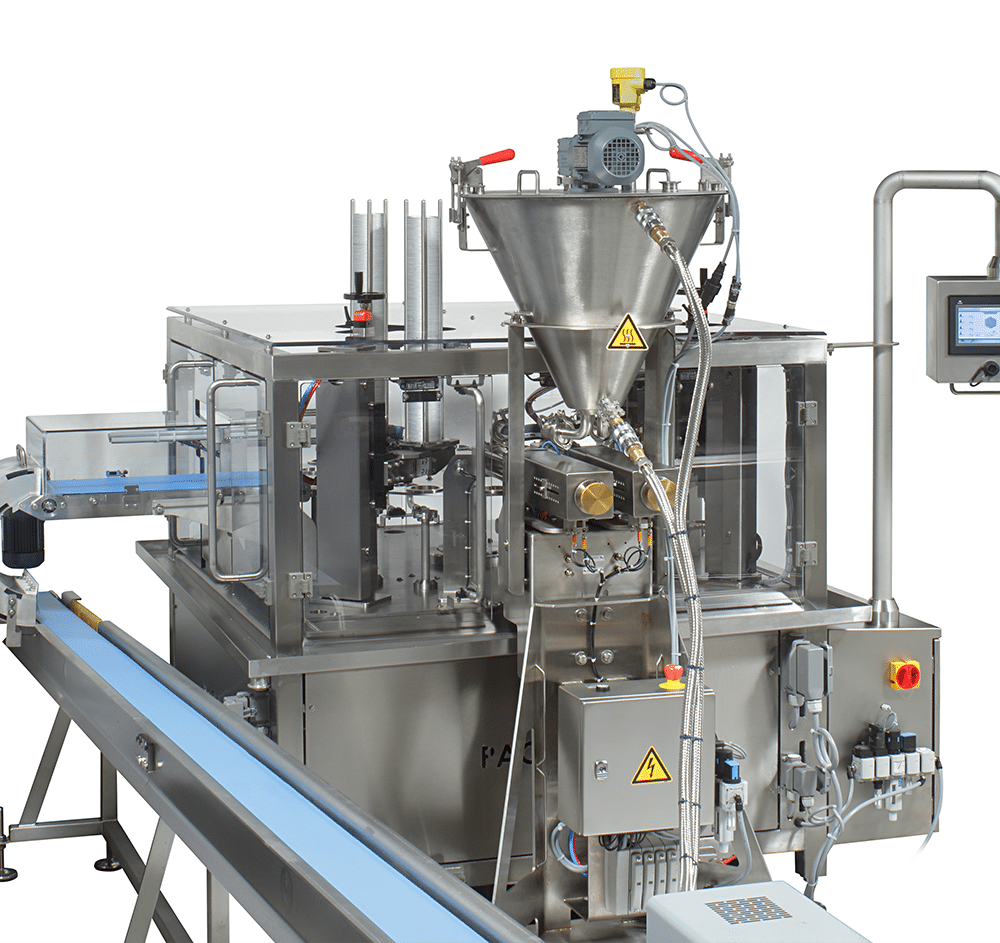

The robustness and durability of packaging machine RMD 844 makes it a a profitable long-term investment. It is designed to withstand the rigours of intensive use, guaranteeing reliability and longevity. Last but not least, its compact, ergonomic design allows easy integration into any production environment.

Up to

pots/hour

French production

- simple and economical

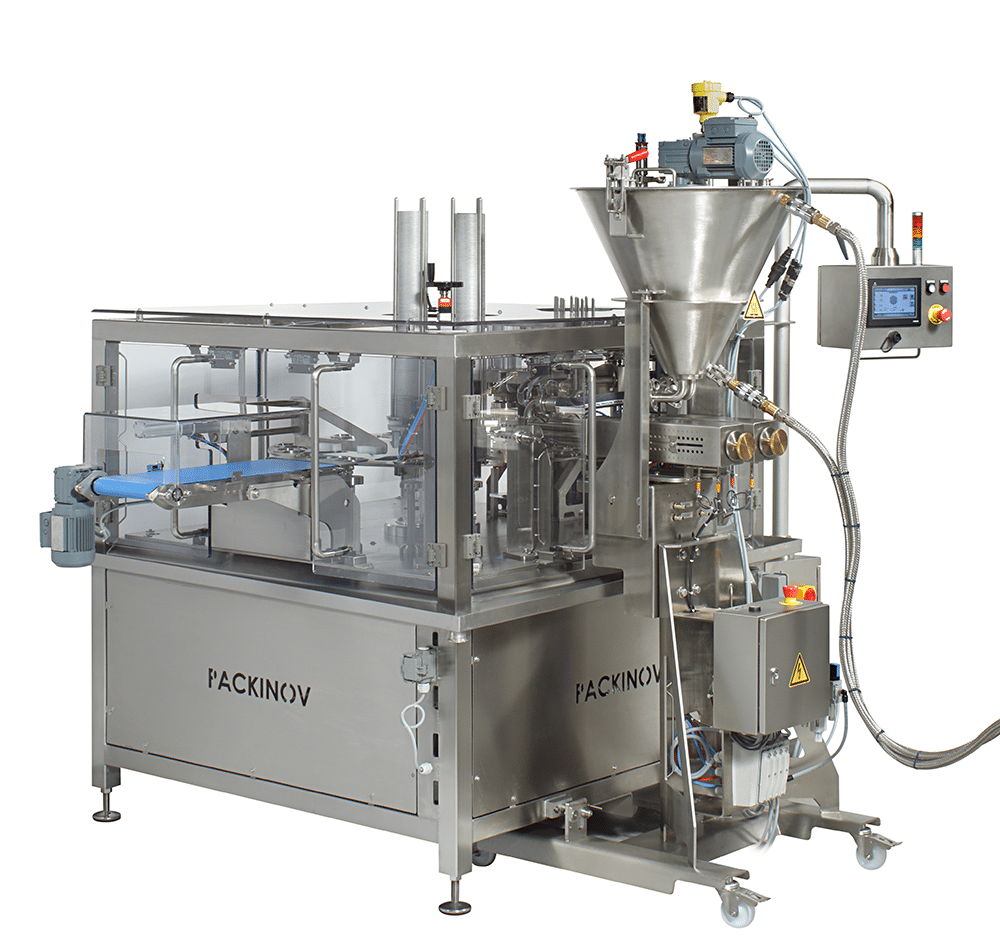

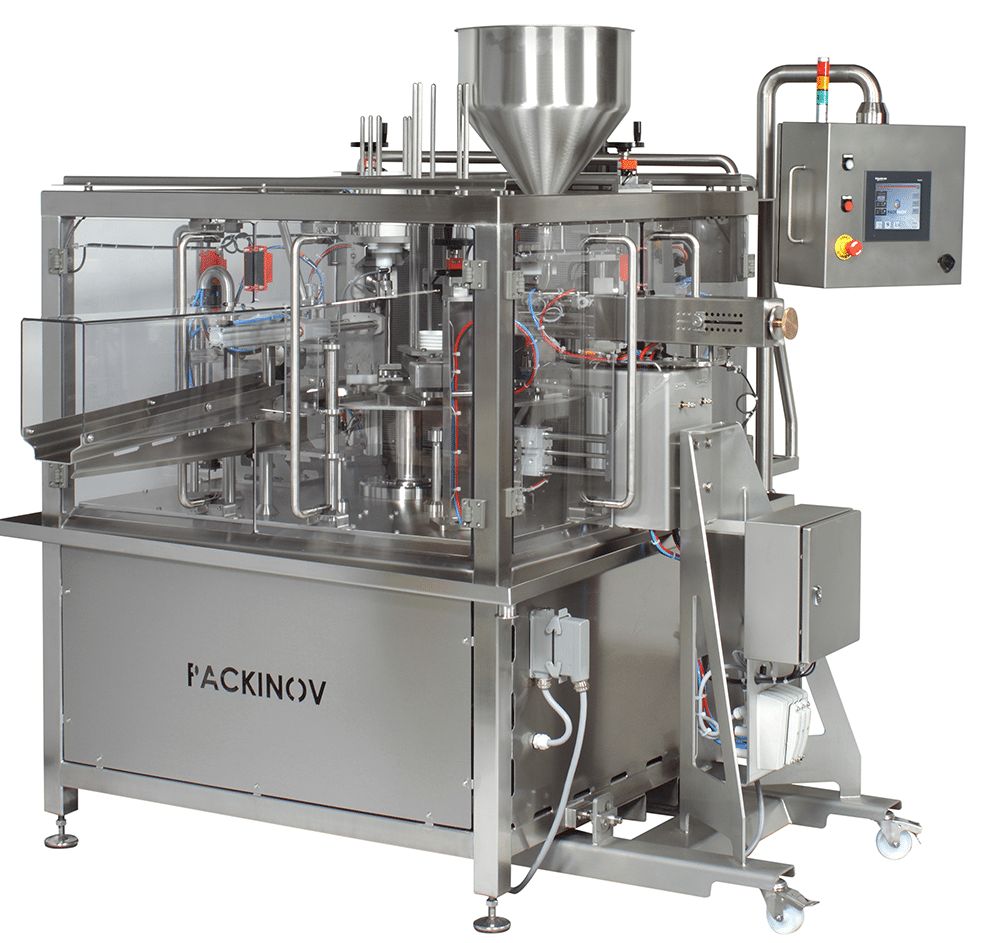

The RMD 844 packaging machine was designed in our in-house office in Franceby our teams. It is simple to operatewith revenue management at the control desk.

It is ideal for products of all sizes, in multiple formats: pots, bowls, trays, cups, etc.

- progressive

The RMD 844 filling machine, like the majority of PACKINOV packaging machines, is progressive.

It's easy to do, respond to new demands from your customers and modernise your machine as the production season progresses.

- dosing precision

PACKINOV dosers are renowned for very precise and regular dosing. Precision is the key to reliable production, reduce tolerance margins and make significant savings on raw materials.

- performance

The RMD 844 filling machine achieves very high High output: up to 8,000 pots/hour. Great performance to make your production profitable.

- easy to clean

Designed entirely in stainless steel for the food industry and compliant with current standards, the RMD 844 packaging machine is very easy to clean whether in CIP, foam cannon or large quantities of water.

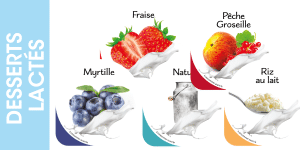

ADAPTED TO YOUR PRODUCTS

Cottage cheese

Fresh cream

Skyr

Cancoillotte

Yoghurts

COMPOST

grout

fruit puree

jam

sauces

mayonnaise

ketchup

SPICES

TEAS

SEL

condiments

Manufacture

100% French

Since 1997, PACKINOV designs and manufactures rotary machines and automatic packaging lines adapted to all products in rigid containers in Beynost (01).

From the outset, this company has opted for the 100% MADE IN FRANCE.

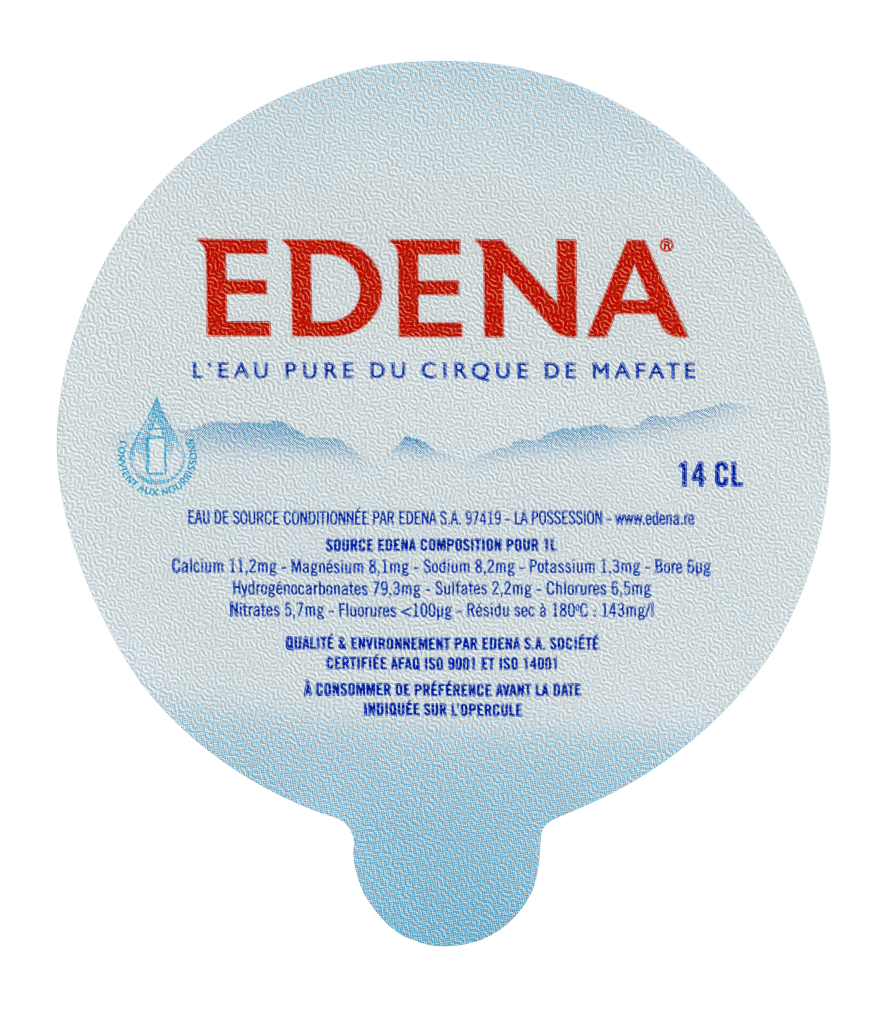

Innovative, top-of-the-range French manufacturer, PACKINOV is present in France and abroad and supports its customers at every stage of their project, in a spirit of partnership. global packaging solution with machines but also pots, the lids and many associated services.

100% made in France

dosing precision

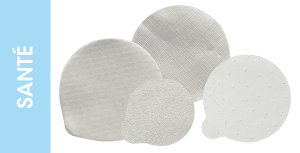

Depilable containers

up to 8,000 pots/hour

The RMD 844 packaging machine

La RMD 844 packaging machine PACKINOV is a innovative multi-format machine designed for unstackable jars offering exceptional versatility, so you can diversify your product range with ease.

La RMD 844 packaging machine is simple and economical. It's ideal for production in jars, bowls, trays, cups and much more. It adapts to a wide variety of unstackable containers, giving you the freedom to flexibility to meet your customers' needs and innovate your product offering.

This packaging machine can be upgraded. It adapts to changes in your business. You can innovate and add to your product range over time, without having to invest in a new machine every time you change.

La RMD 844 packaging machine also stands out for its high dosing accuracy, up to +/-0.5%. You can count on consistent packaging quality for your products, whatever their format.

This machine offers impressive performance, with a speeds of up to 8,000 pots per hour on several lanes.

The machine is very easy to use, with just one touch of a button. management of receipts at the desk orders and a dismantling without tools for simplified maintenance. What's more, it's complies with current food standardsAll stainless steel construction to guarantee the safety of your products. The cleaning has also been simplifiedWith options such as CIP, high water and foam cannon.

Designed for

Large containers

Beverage cartons

Plastic pots

Metal bowls

The RMD 844 packaging machine is multi-format, high-speed and scalable to maximise your productivity.

Benefits of the RMD 844 packaging machine

- Very high productivity: up to 8,000 pots/hour

- High dosing accuracy

- Modularity, multi-format packaging machine

- Flexible, suitable for depilable containers of different volumes

- Easy to use, quick format changeover

- Optimised design and ergonomics to meet your requirements

- Easy to clean

- All stainless steel for foodstuffs, 100% made in France

Discover the rmd 844 in video

Reading list

RMD 844 packaging machine suitable for :

to the RMD 844 packaging machine

After-sales services

PACKINOV's after-sales service is at your side to maintain, repair and upgrade your machine, filler or dispenser.

You can also consult our after-sales guides for routine maintenance of your machine.

FUNDING ASSISTANCE

PACKINOV can help you with the administrative procedures involved in financing your machine.

Our machines are eligible for AGILOR, AGRILISMAT and ACTIMAT financing, and can be leased.

RENTAL

Keep all the flexibility you need to get your business off the ground.

Our machines are available for hire to enable you to launch your new products quickly and help your business grow.

Maintenance

PACKINOV's teams carry out annual maintenance on your machine and replace wearing parts to ensure that your filling machine operates at optimum efficiency and that your production continues uninterrupted.

Manufacture

100% French

All our machines are developed and manufactured in France.

Discover our production site in pictures.

You're delighted

They trust us