HACCP and agri-food standards

HACCP and compliance

The Hazard Analysis Critical Control Point (HACCP) system is a tool used by companies in the agri-food sector to guarantee food safety.

This system was originally developed in the 1960s to produce safe and healthy food for a US space programme.

Based on prevention and risk analysis, this system enables food companies to identify critical control points (CCPs) for physical (e.g. glass), chemical (e.g. pesticides) and microbiological (e.g. bacteria responsible for food poisoning) risks, before they compromise food safety.

By law, all European food companies must introduce and apply procedures based on the principles of the HACCP system. The implementation of an HACCP system involves first and foremost the application of good hygiene practice (GHP).

BPH covers, for example, personal hygiene and staff training; cleaning and disinfection; maintenance and upkeep; pest control; facilities and equipment; premises and structures; preservation, distribution and transport; and waste management.

Stricter hygiene rules apply to primary producers such as farmers.

Standards often provide manufacturers with the necessary information on the procedures to be put in place.

IT IS FORBIDDEN TO COMMISSION OR USE A MACHINE WHICH DOES NOT COMPLY WITH THE REGULATIONS.

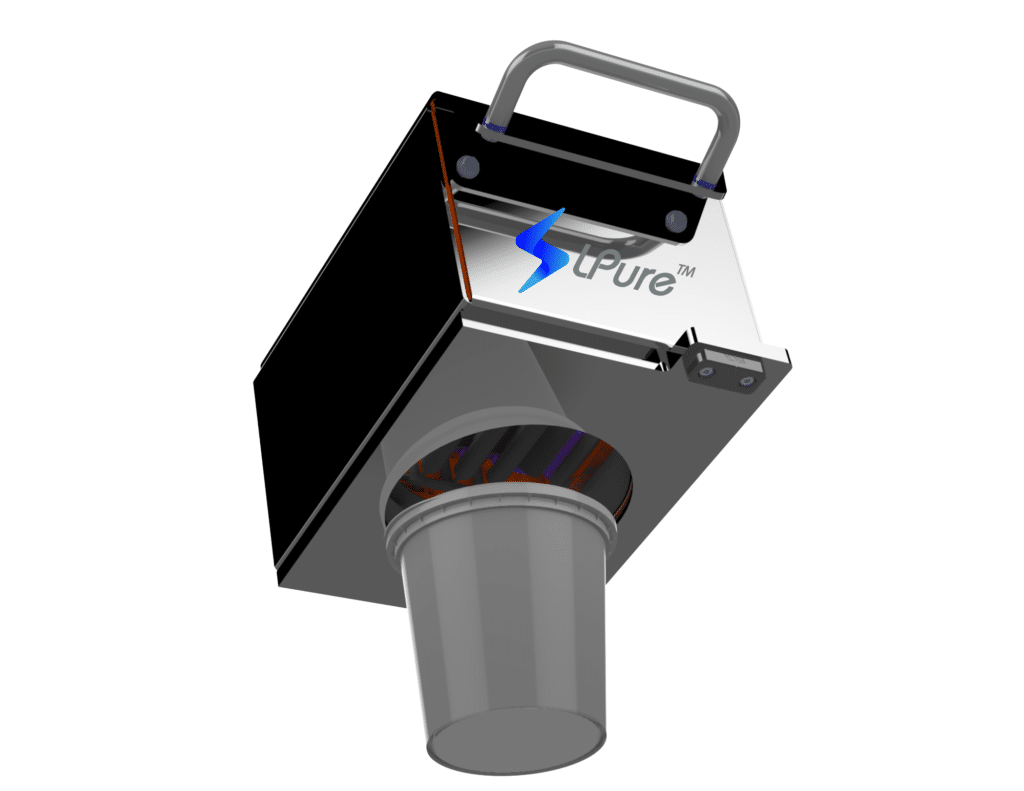

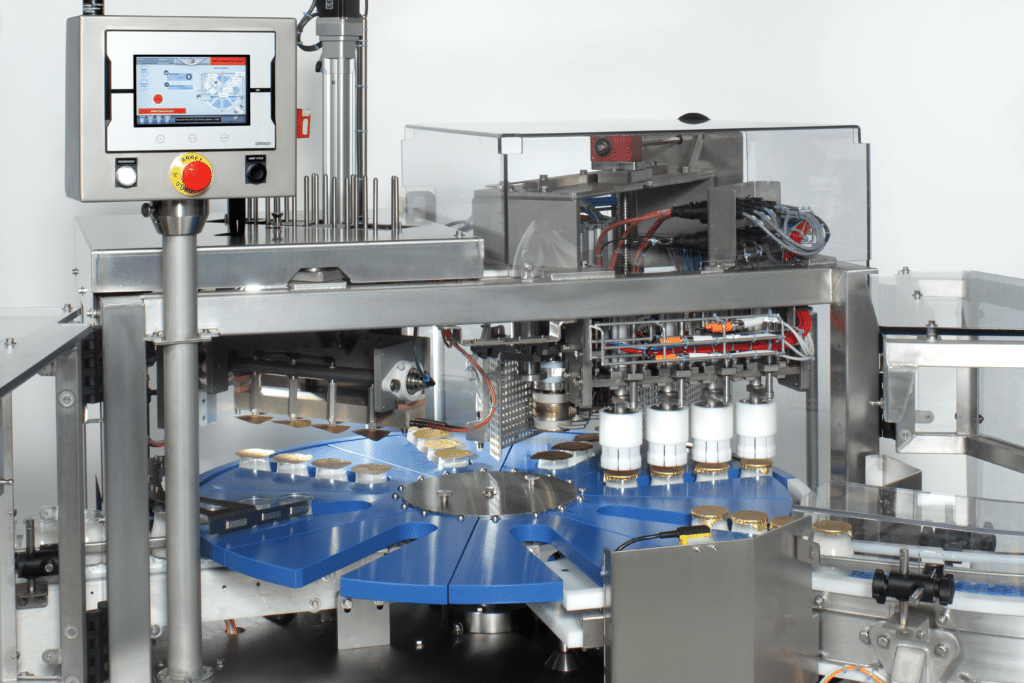

AUTOMATIC AND SEMI-AUTOMATIC

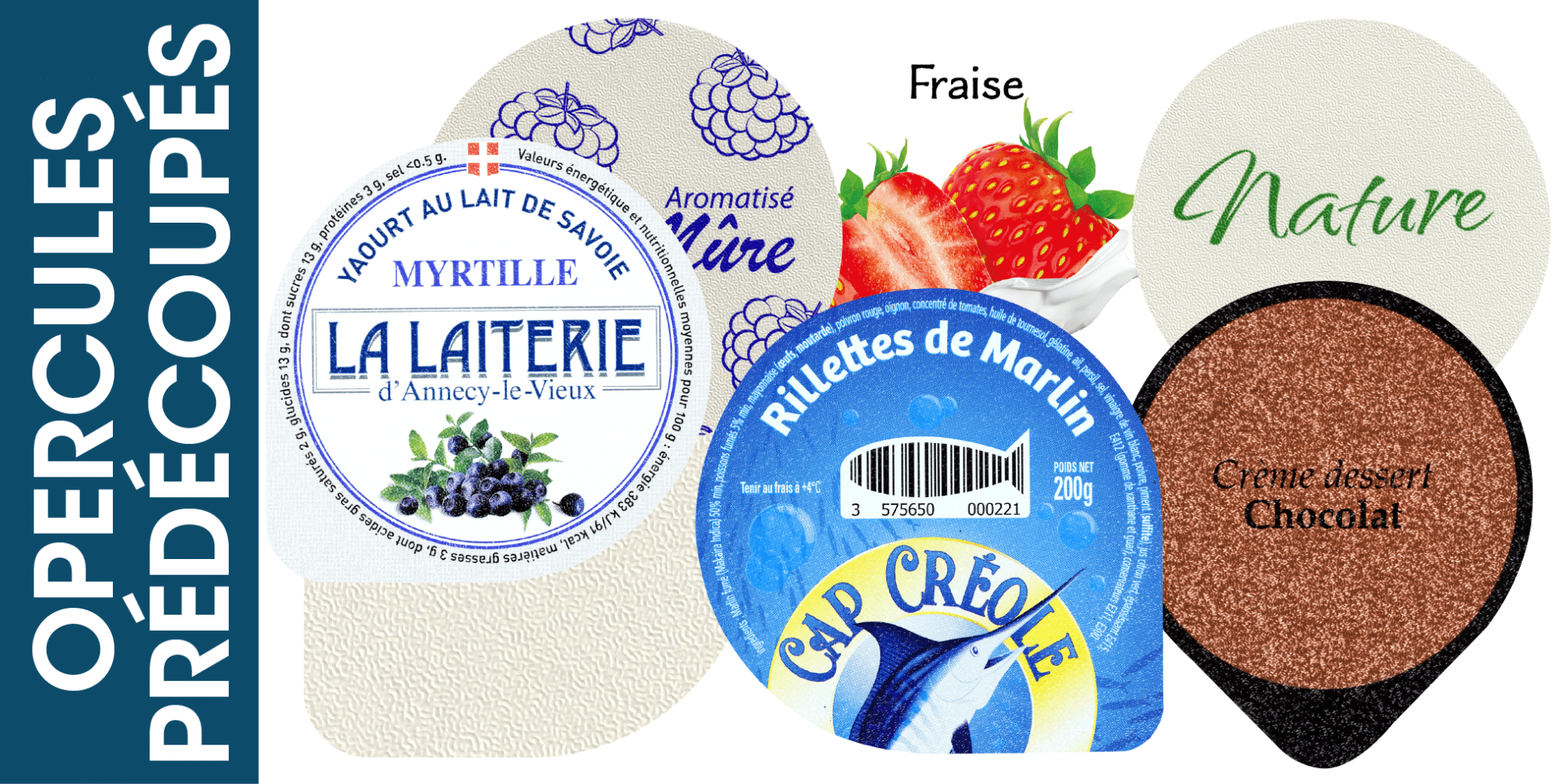

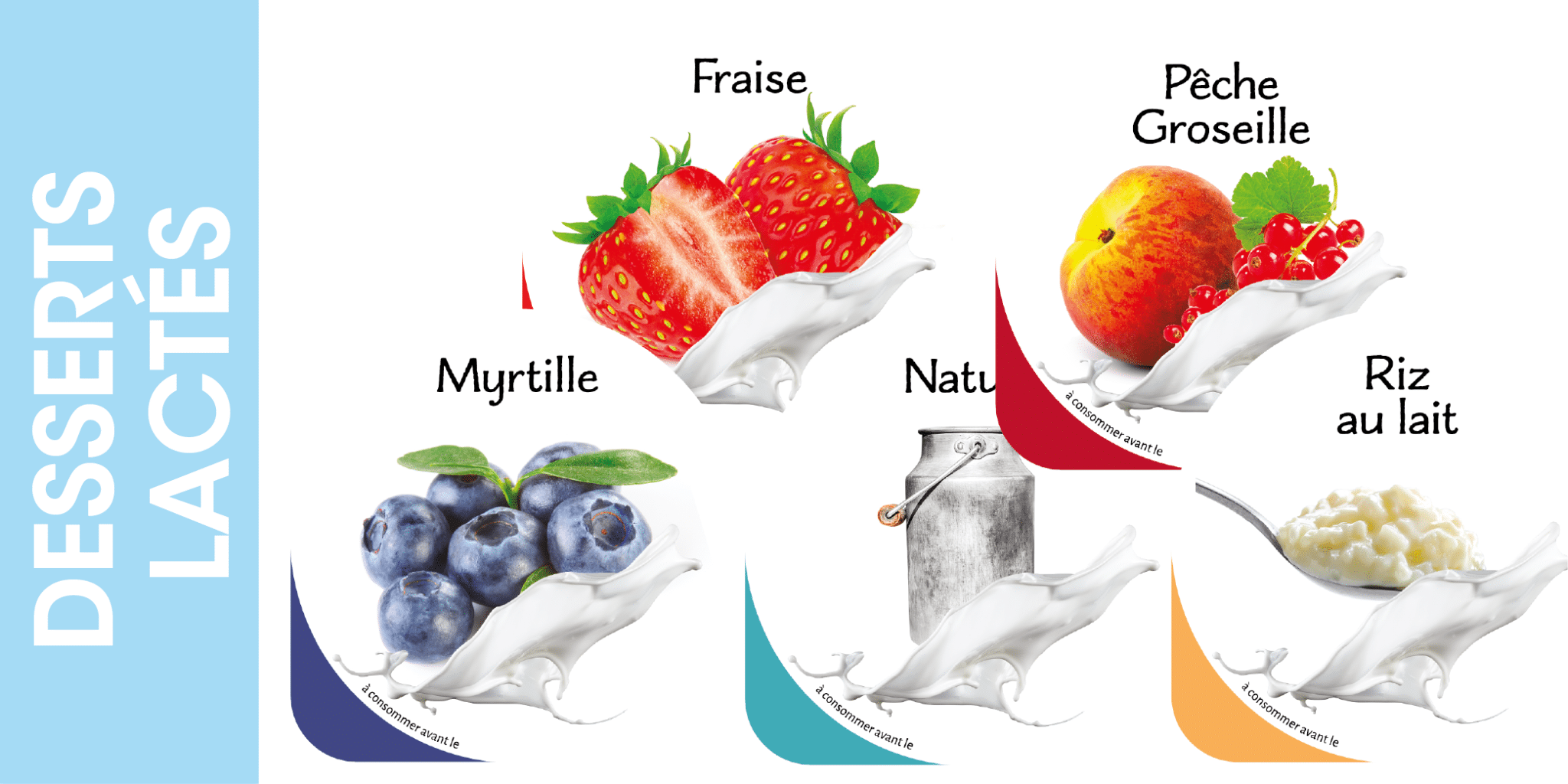

- Suitable for solid, unstackable or non-stackable containers.

- Optimised ergonomics

- Easy to clean

- Independent modules

- Ideal for starting production

- Output between 1500 and 3300 pots/h

- Available, in stock

- Guaranteed after-sales service

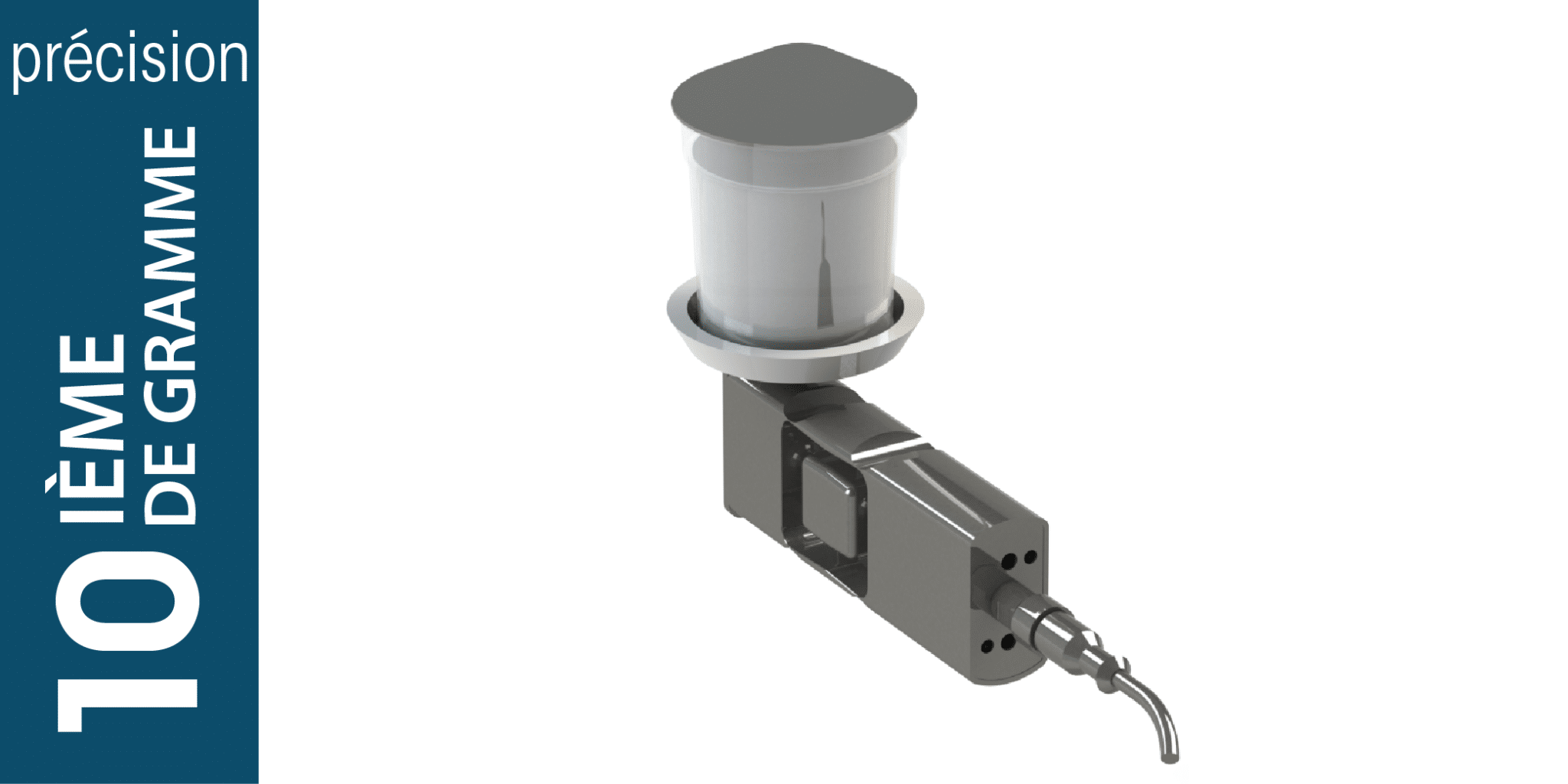

Weighing control module

TH500 heat sealer

RMC 840 packaging machine

RMC 814 packaging machine

RMD 844 packaging machine

RMD Nano packaging machine

PACKINOV is a Member of the ehedg since 2018

agri-food standards

Food standards are generally drawn up by national or international bodies, such as the International Organisation for Standardisation (ISO), which are specifically responsible for developing standards and/or food safety, or by the food industry itself, through a representative body such as the British Retail Consortium (BRC).

Agri-food standards play a key role in helping agri-food businesses to consistently produce safe and healthy food in compliance with current legislation.

At present, many standards can be checked or certified by independent bodies such as Société Générale de Surveillance (SGS). However, certification does not prove that a food is safe, but simply that it has been produced under a quality system that has been correctly applied. It is a cost-effective system for controlling product quality and safety. It is also a way for food companies to affirm their commitment to food safety, and to demonstrate the level of confidence expected by consumers and regulatory authorities alike.

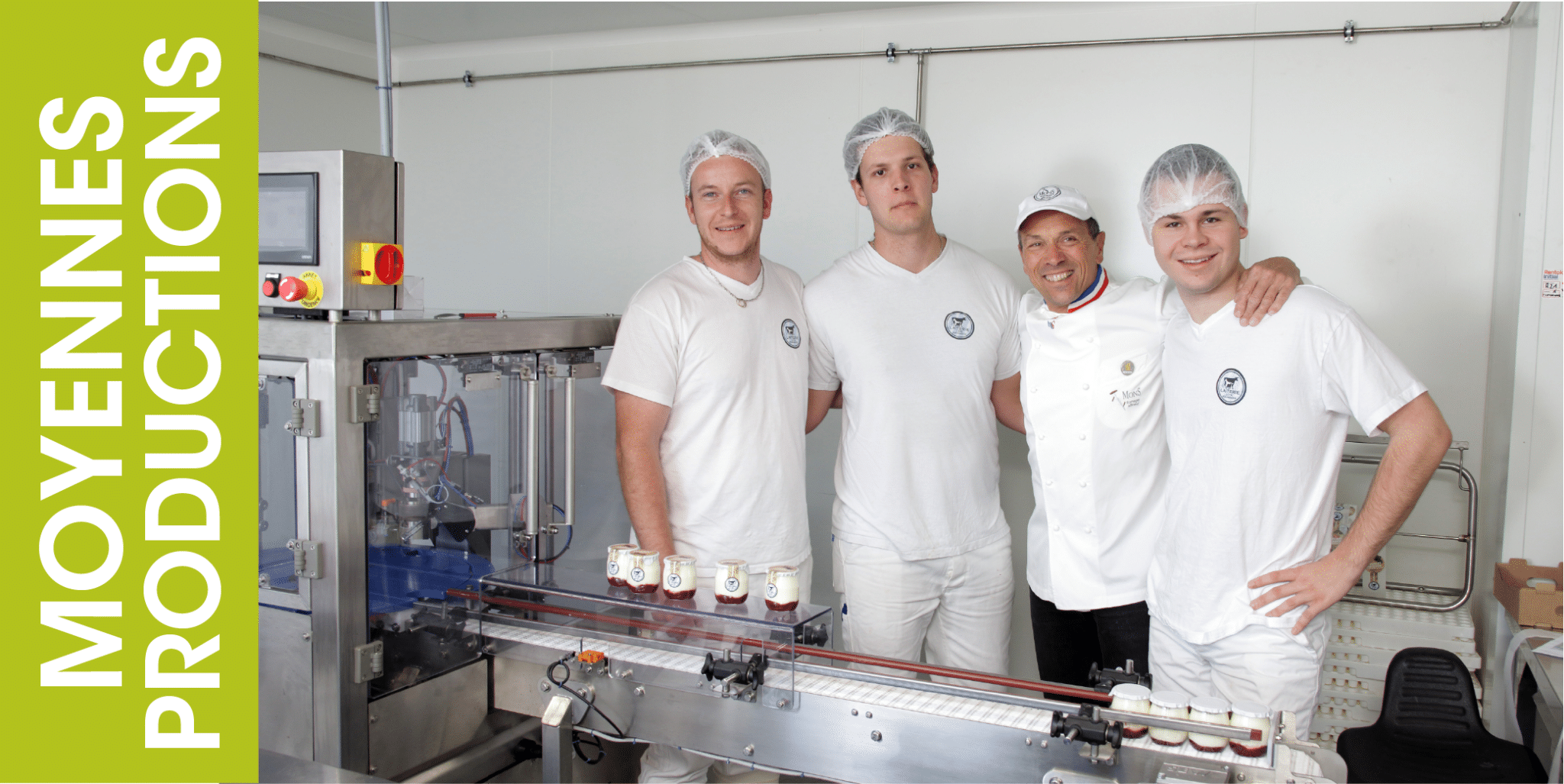

They trust us

100% French design and manufacture

All our semi-automatic and automatic machines are designed and manufactured in France by our in-house Design Office, at our production site in Beynost in the Ain department, in the heart of the Auvergne-Rhône-Alpes region. More than just a sales argument, at PACKINOV, 100% French manufacturing is a reality and almost an obsession!

And our objectives are clear: to reach 100% of PACKINOV subcontracting partners in France, so that we can play an active role in the national revival and momentum.

Today, our results are already very positive, with over 98% from our partners based in France, including 73% in the Auvergne Rhône Alpes region and 19% in the Ain. And the others are all European!