CIP & NEP

nep or cip, a must

The water circuit used for cleaning, as well as the supply and possible reprocessing of the wash water, are integrated into the design of the tooling. In automated machines, cycles and programmes are also integrated from the outset. In this case, the main pumps or auxiliary pumps can be used to move the water.

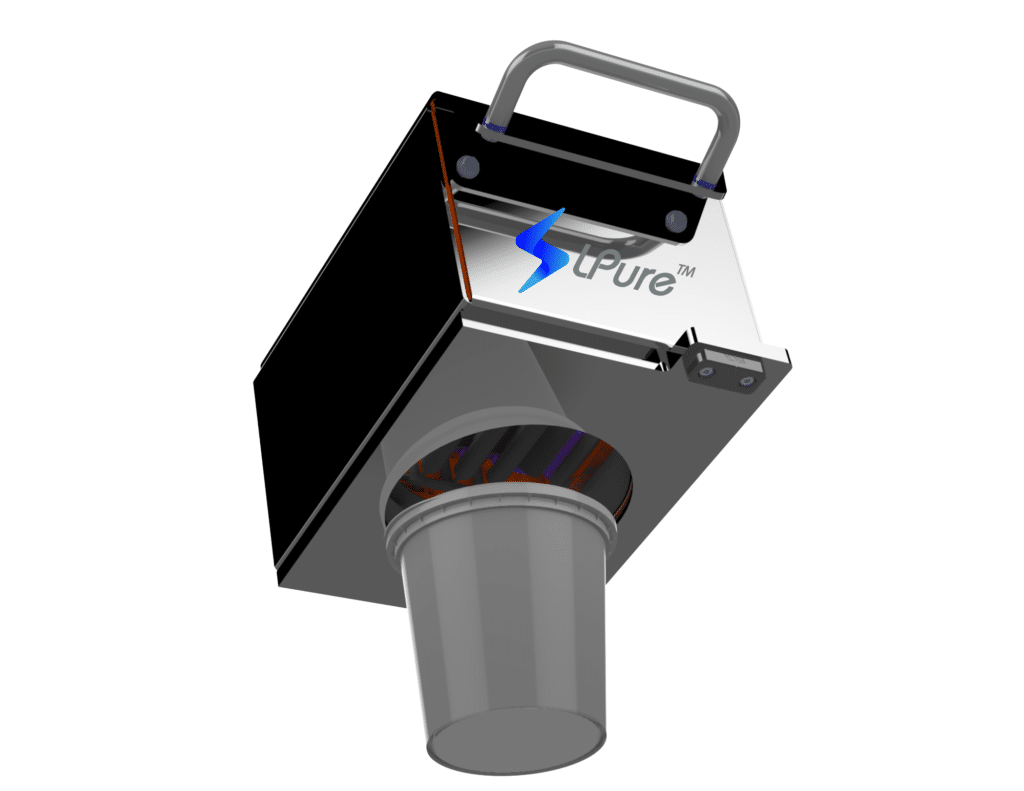

CIP is not based solely on the use of cleaning water. To purge a pipe, for example, a shuttle can be used, which scrapes the inner wall and pushes out any product residues as it moves through the pipe. The shuttle is introduced via a bypass circuit or through an opening in the main pipe. The shuttles are pushed through the pipe by air or water, or sometimes directly by the next product.

Some manufacturers offer water treatment systems that can be used for CIP, integrating pumps, filters and water heating in a mobile machine.

PACKINOV offers packaging lines adapted to a CIP system : tanks, dosing systems, etc. and can help you design your mobile CIPs for your production workshop or laboratory.

PACKINOV offers packaging lines

adapted to a CIP system tanks, dosing systems, etc.

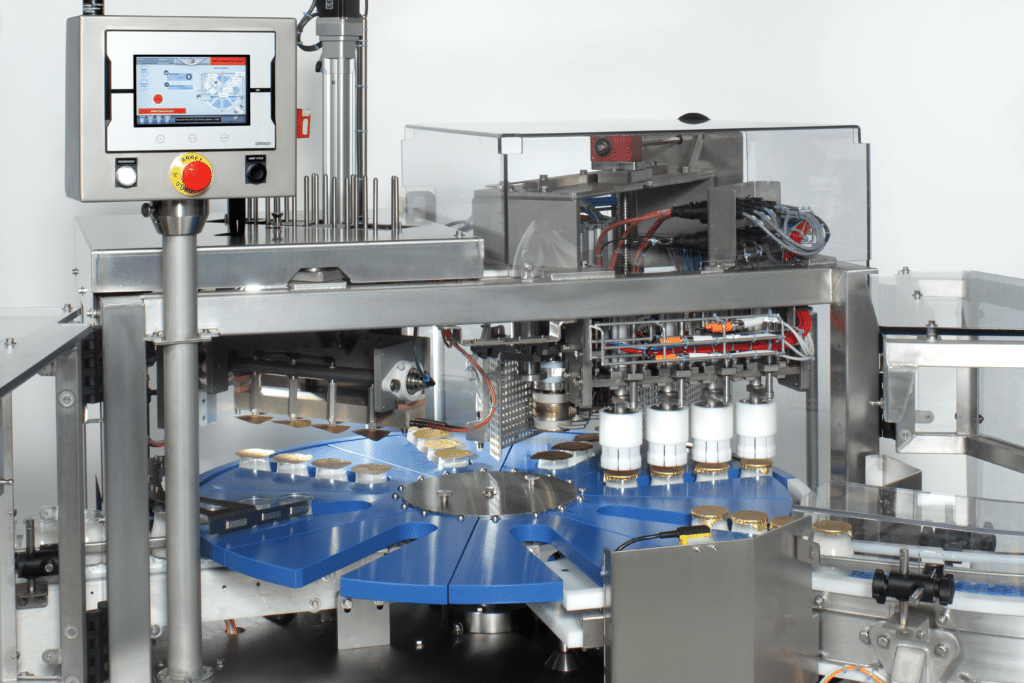

AUTOMATIC AND SEMI-AUTOMATIC

- Suitable for solid, unstackable or non-stackable containers.

- Optimised ergonomics

- Easy to clean

- Independent modules

- Ideal for starting production

- Output between 1500 and 3300 pots/h

- Available, in stock

- Guaranteed after-sales service

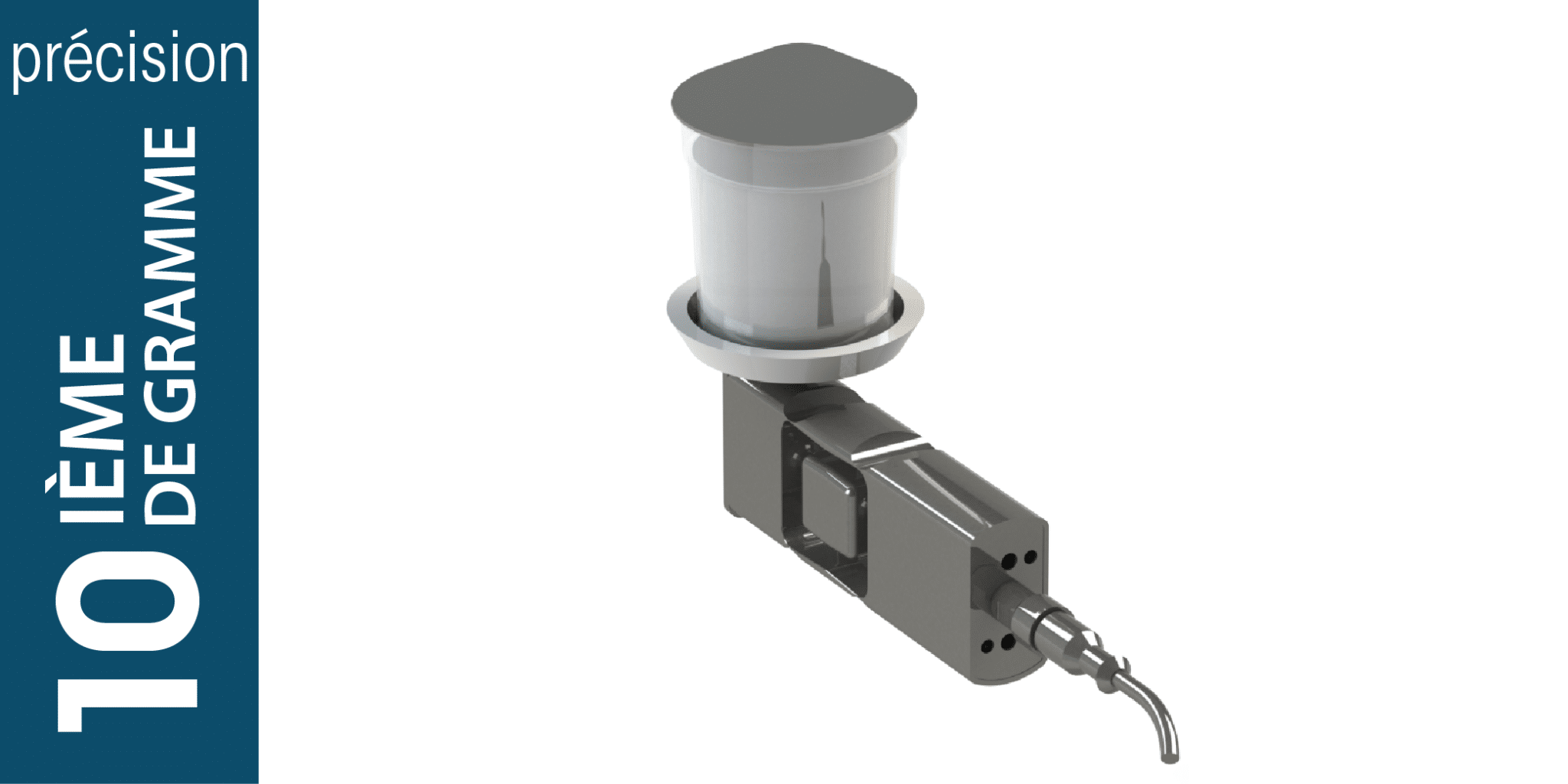

Weighing control module

TH500 heat sealer

RMC 840 packaging machine

RMC 814 packaging machine

RMD 844 packaging machine

RMD Nano packaging machine

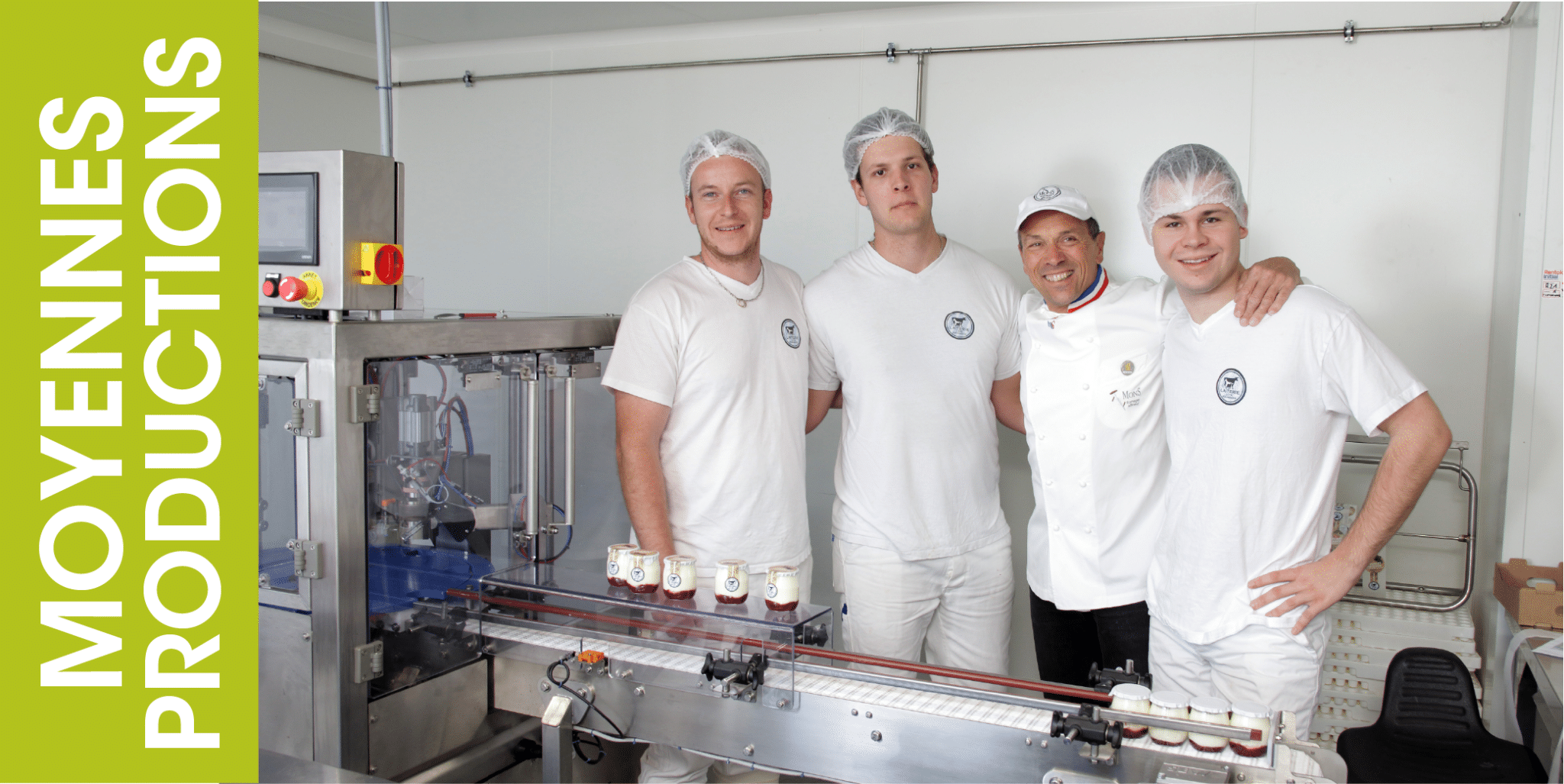

They trust us

100% French design and manufacture

All our semi-automatic and automatic machines are designed and manufactured in France by our in-house Design Office, at our production site in Beynost in the Ain department, in the heart of the Auvergne-Rhône-Alpes region. More than just a sales argument, at PACKINOV, 100% French manufacturing is a reality and almost an obsession!

And our objectives are clear: to reach 100% of PACKINOV subcontracting partners in France, so that we can play an active role in the national revival and momentum.

Today, our results are already very positive, with over 98% from our partners based in France, including 73% in the Auvergne Rhône Alpes region and 19% in the Ain. And the others are all European!