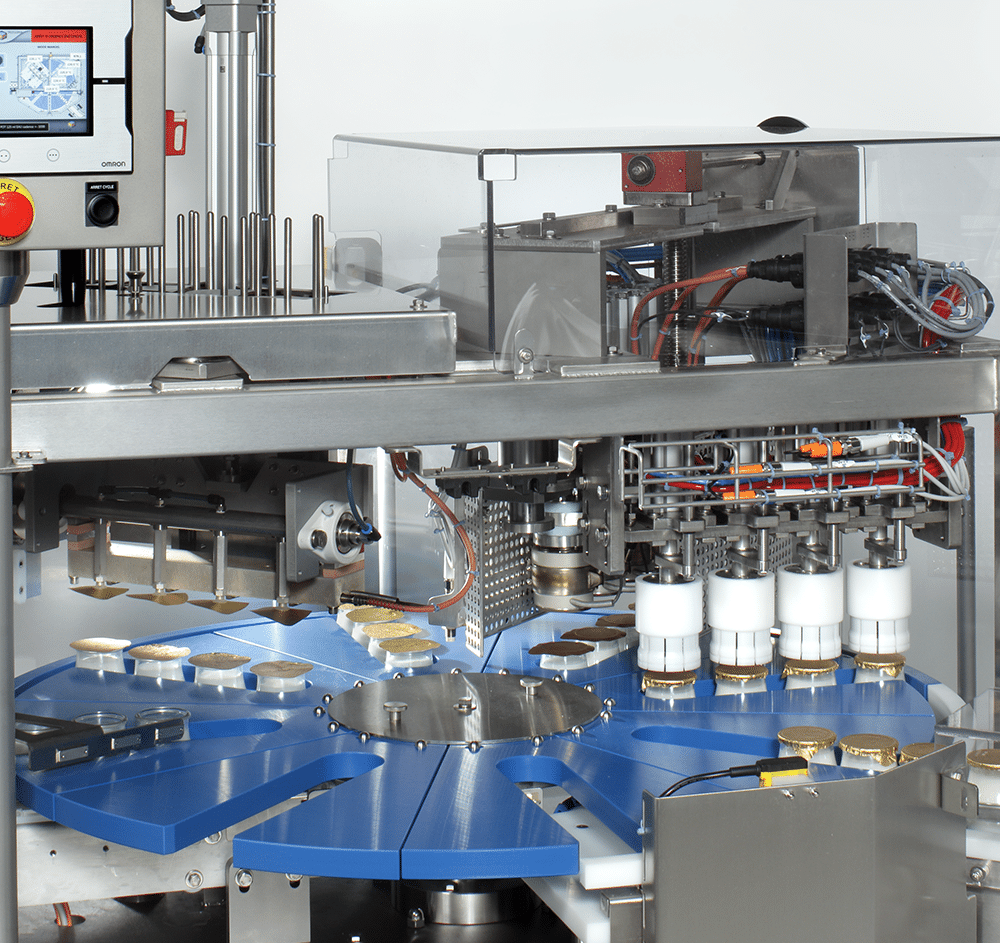

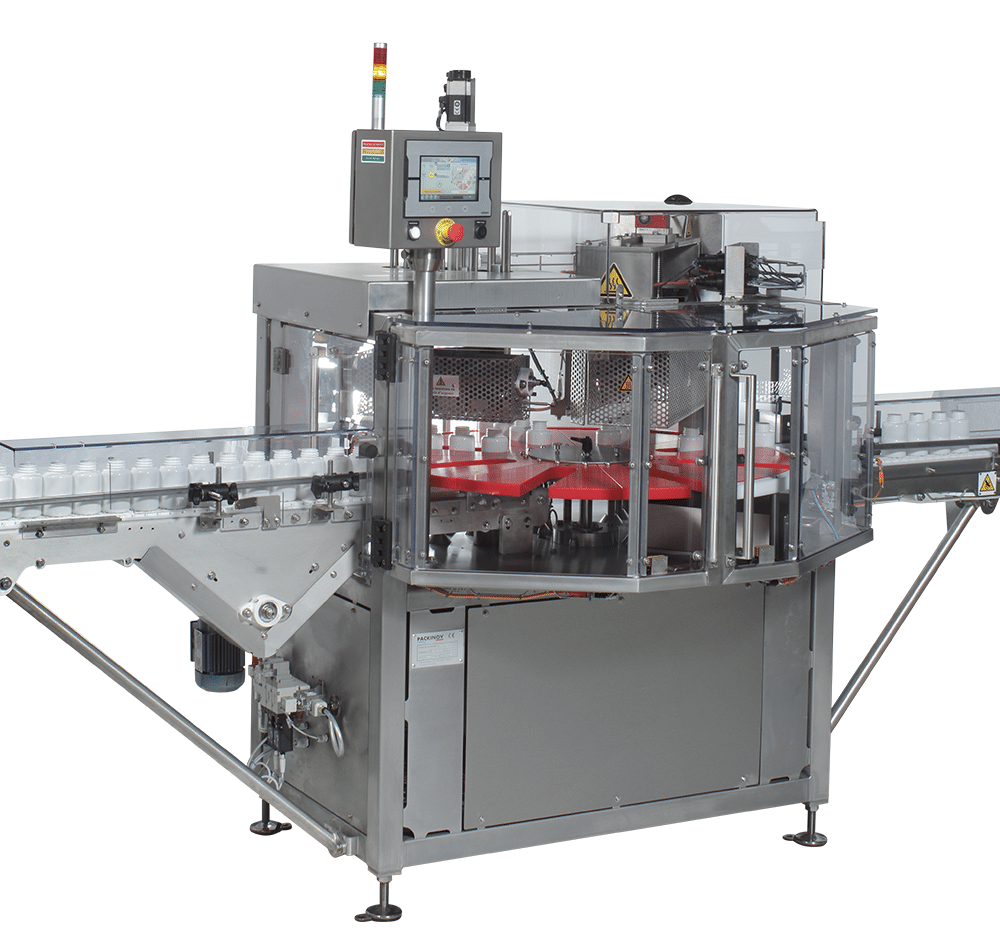

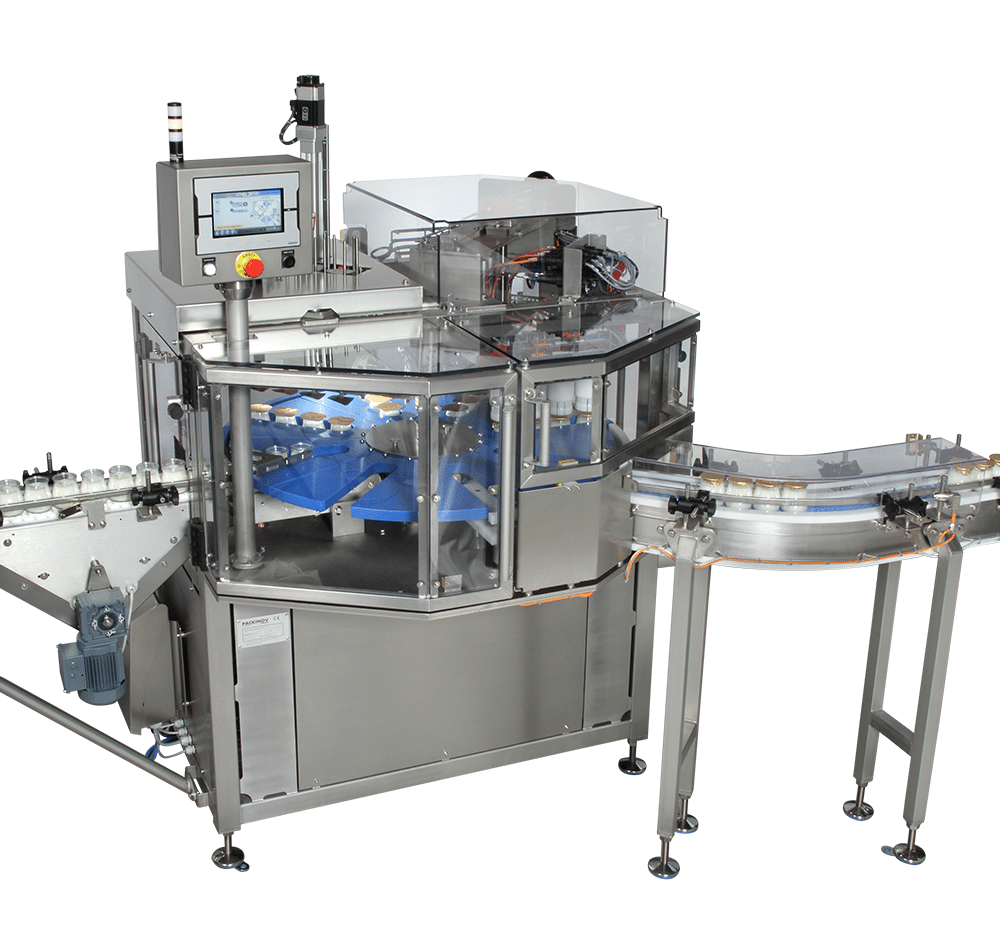

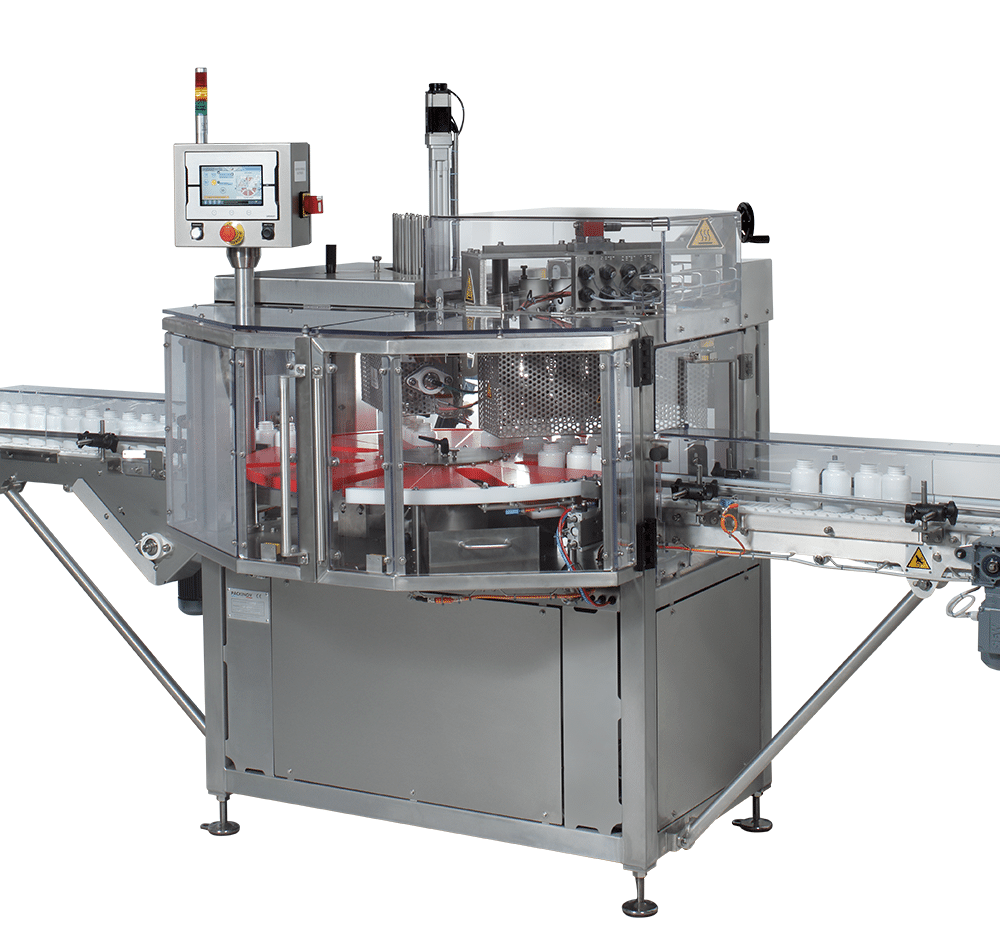

rmc 840 packaging machine

An ultra-compact high-speed heat-sealing machine

In a constantly changing industrial world, efficiency, speed and space optimisation are essential criteria. This is where the conditioner ultra-compact RMC 840 heat sealer comes into play. Designed and manufactured in France to meet the high-speed requirements of the cosmetics, pharmaceutical and food industriesthis packaging machine redefines the standards for automated packaging.

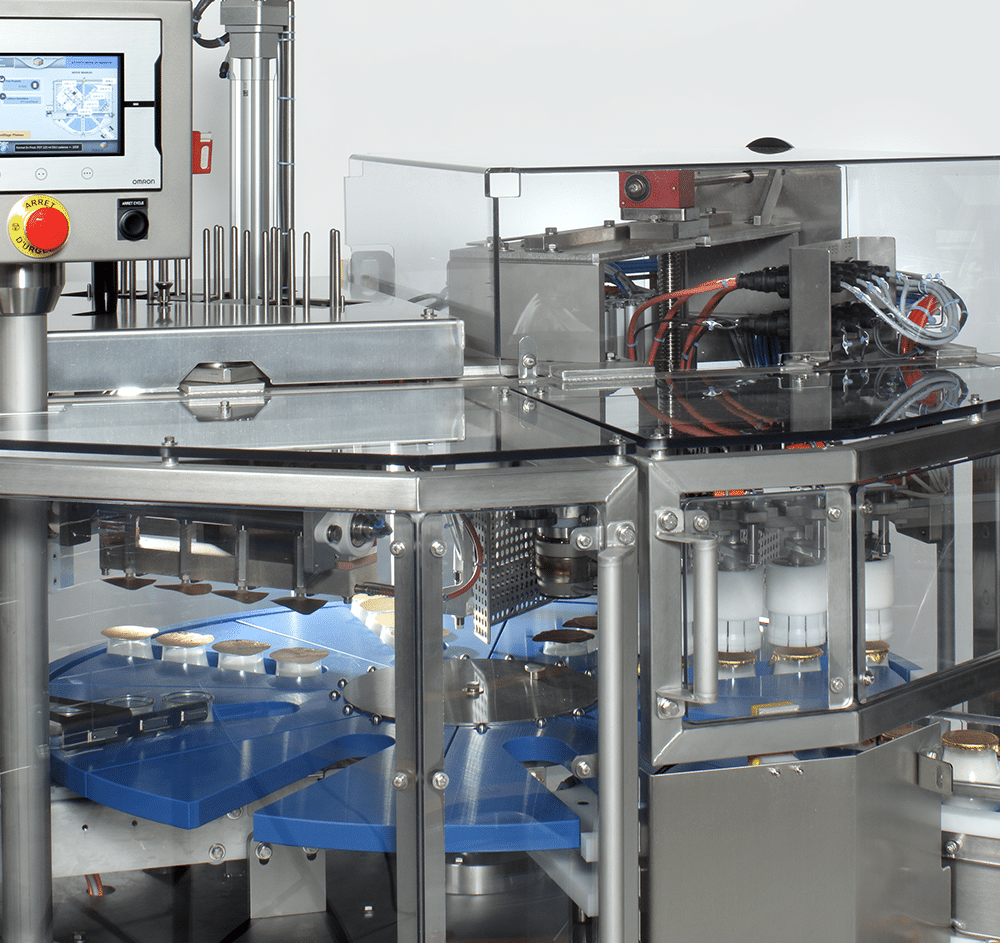

The RMC 840 packaging machine is a symbol of speed and space optimisation. Its design compact makes it an ideal solution for companies looking to maximise their production space. Despite its reduced footprint, it doesn't compromise the pace. On the contrary, it excels in packaging, dosing and heat-sealing a variety of productsThis means that the machine can handle a wide range of materials, whether liquids, pastes or solids, at high speed.

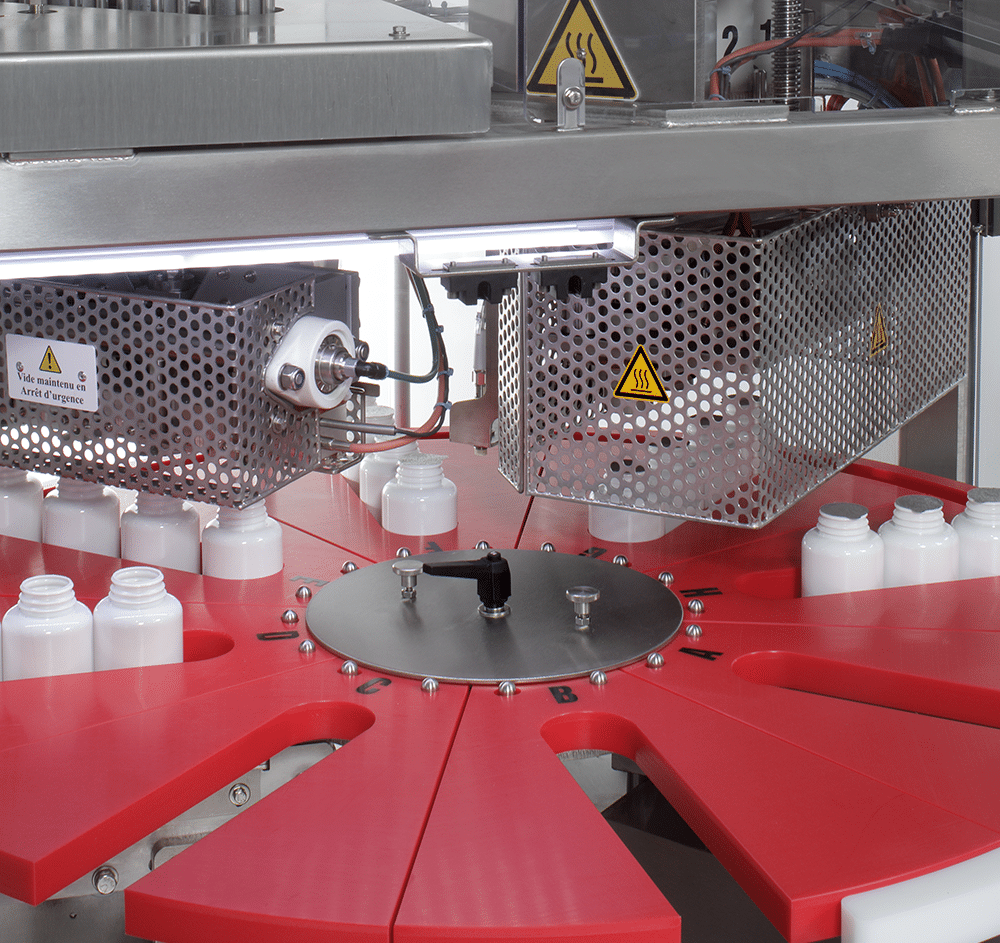

Non-strippable containers such as glass jars, bottles and other containers can be processed efficiently by this machine. It ensures a sustained rate of production, enabling companies to respond rapidly to market demands.

Compact but powerfulthe RMC 840 packaging machine is designed to integrate easily into any production environment. With a footprint of around 1 square metre, it offers a practical solution for production sites where space can be a constraint.

Up to

pots/hour

Manufacture

French

- ultra-compact

Designed by our in-house design office in France, the RMC 840 heat-sealing machine is very compact and has a very small footprint, making it easy to fit into any production site.

- high performance

The RMC 840 heat-seal packaging machine achieves high multi-track output: 7,000 pots/hour. Great performance to help you grow your business.

- easy to clean

Designed entirely in stainless steel for the food industry and complying with current standards, the RMC 840 packaging machine is very easy to clean whether in CIP, foam cannon or large quantities of water.

- progressive

Like all PACKINOV machines, the RMC 840 heat-sealing machine has been designed and manufactured on our production site in France.

It is progressive in line with your expectations and new market needs. A major advantage if you want to keep up with trends without having to change your machine!

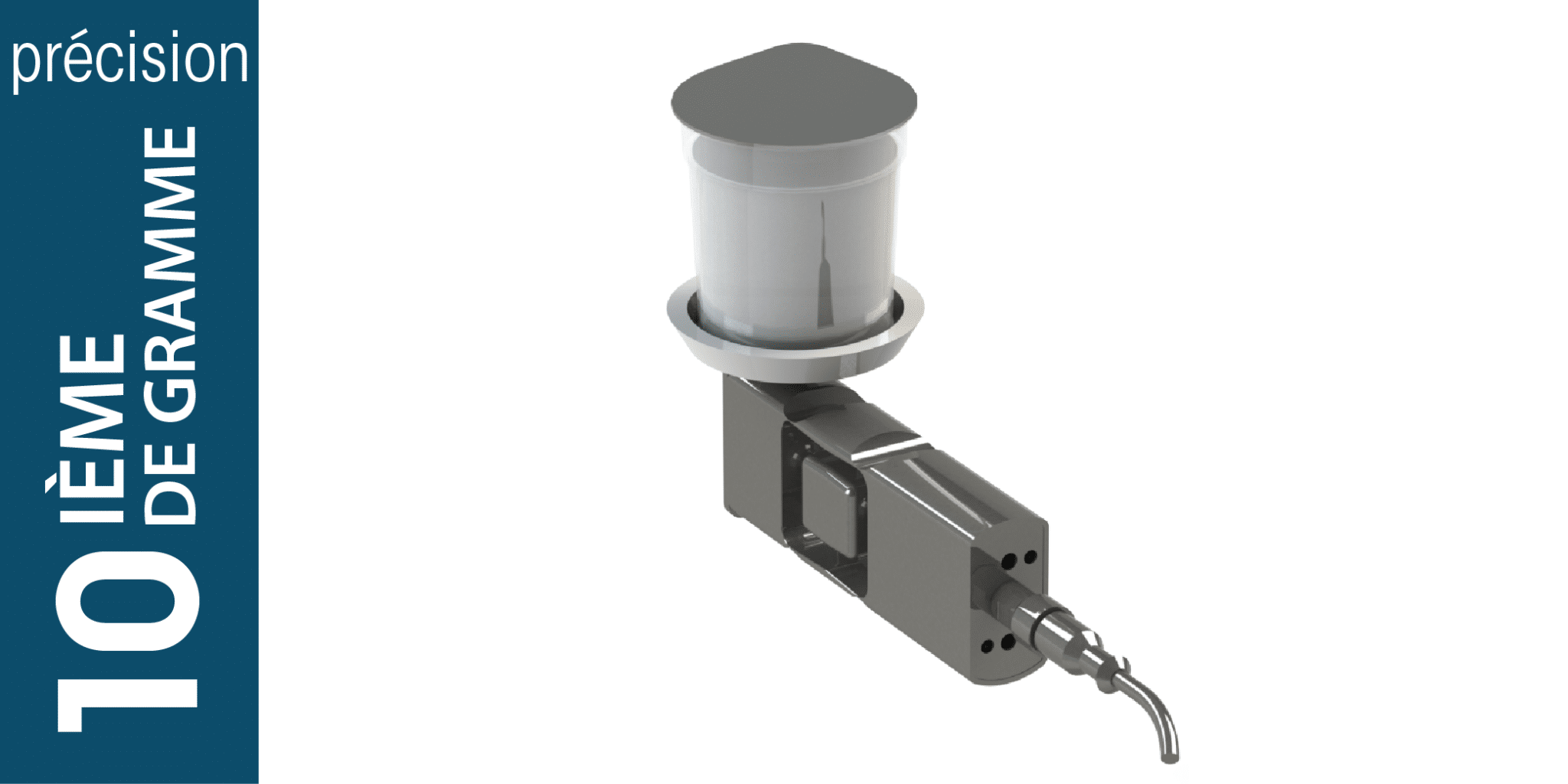

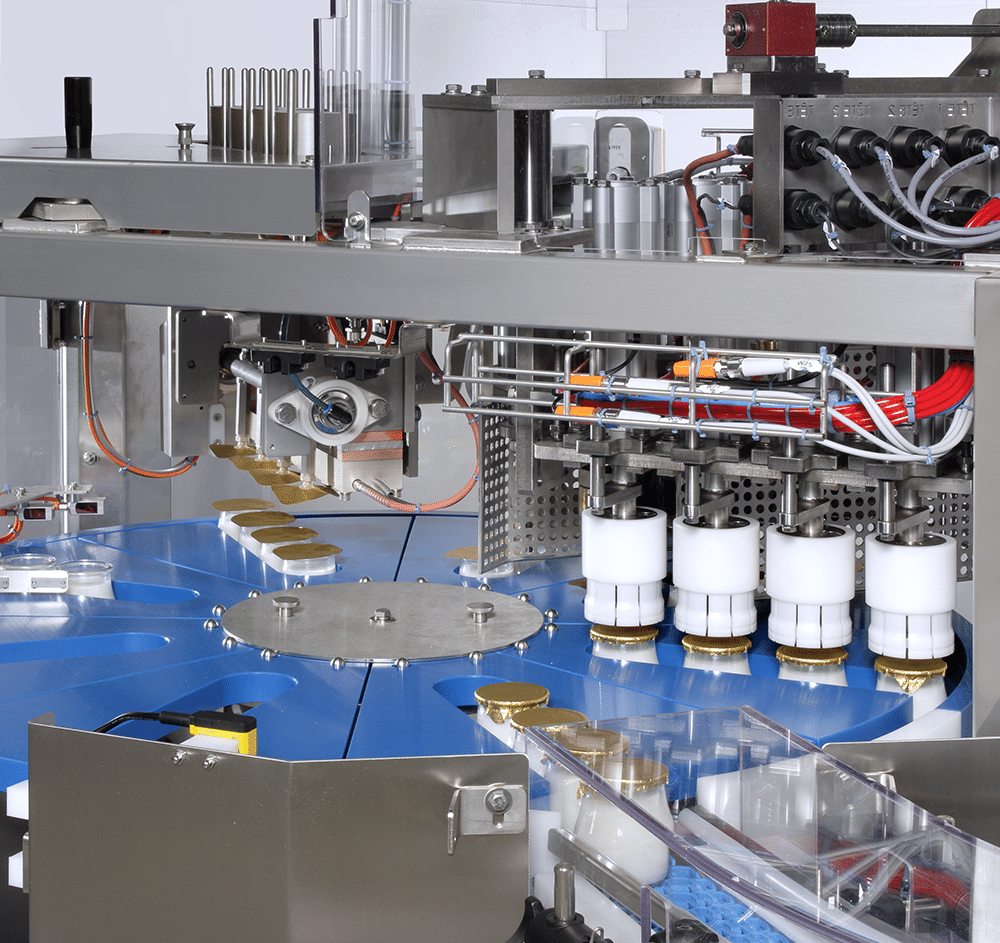

- dosing precision

PACKINOV dosers are renowned for very precise and regular dosing. Precision is the key to reliable production, reduce tolerance margins and make significant savings on raw materials.

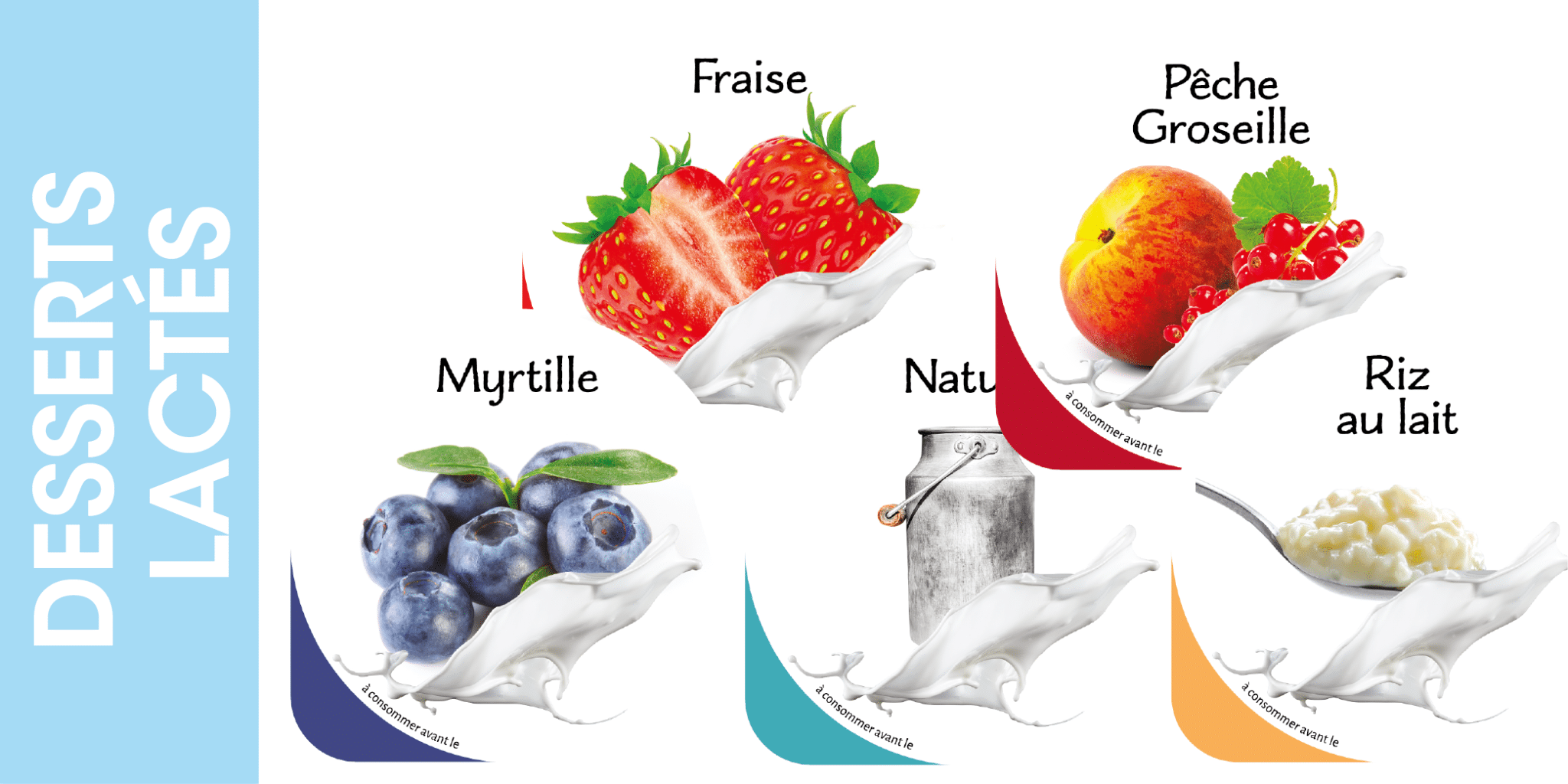

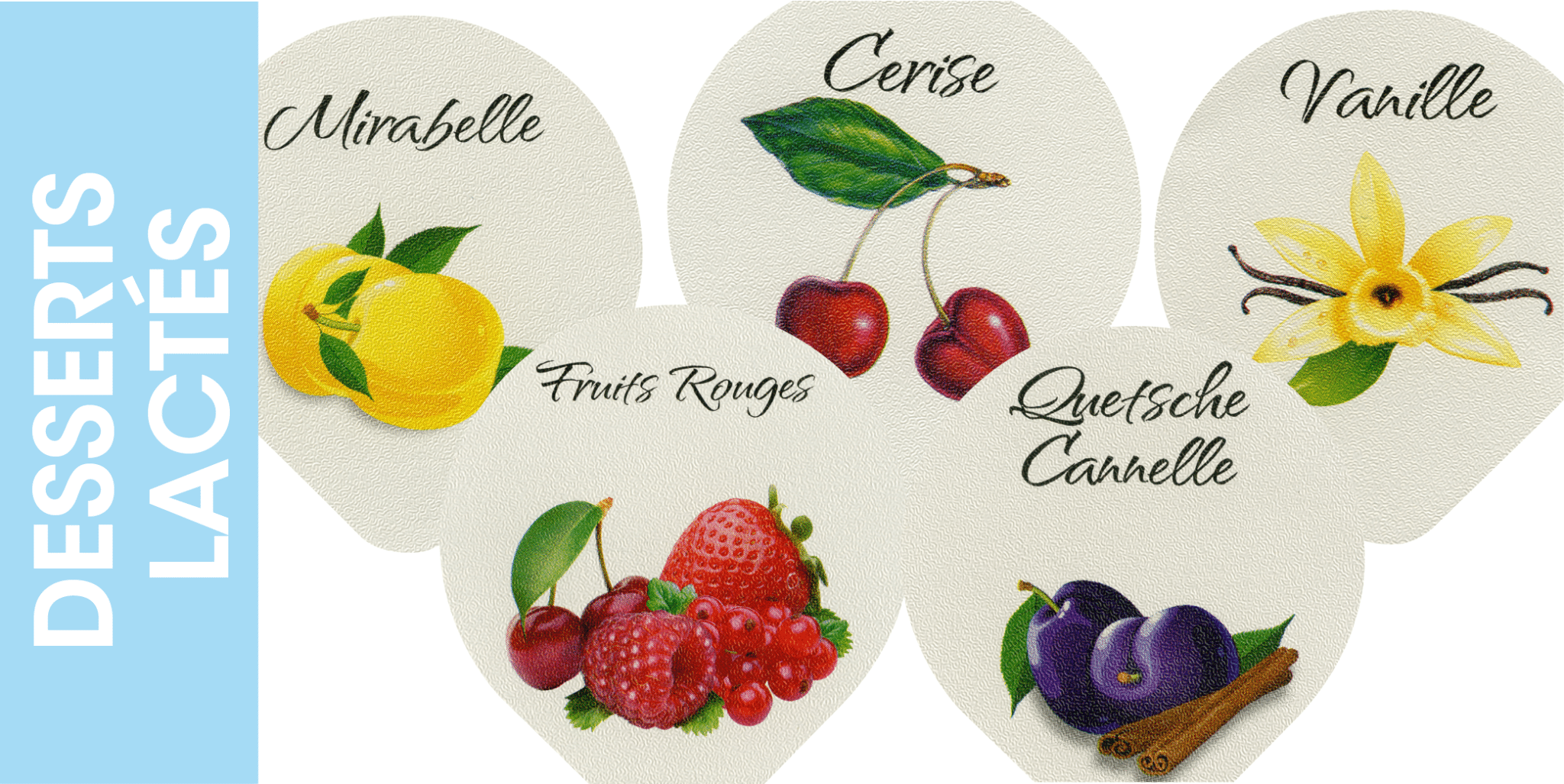

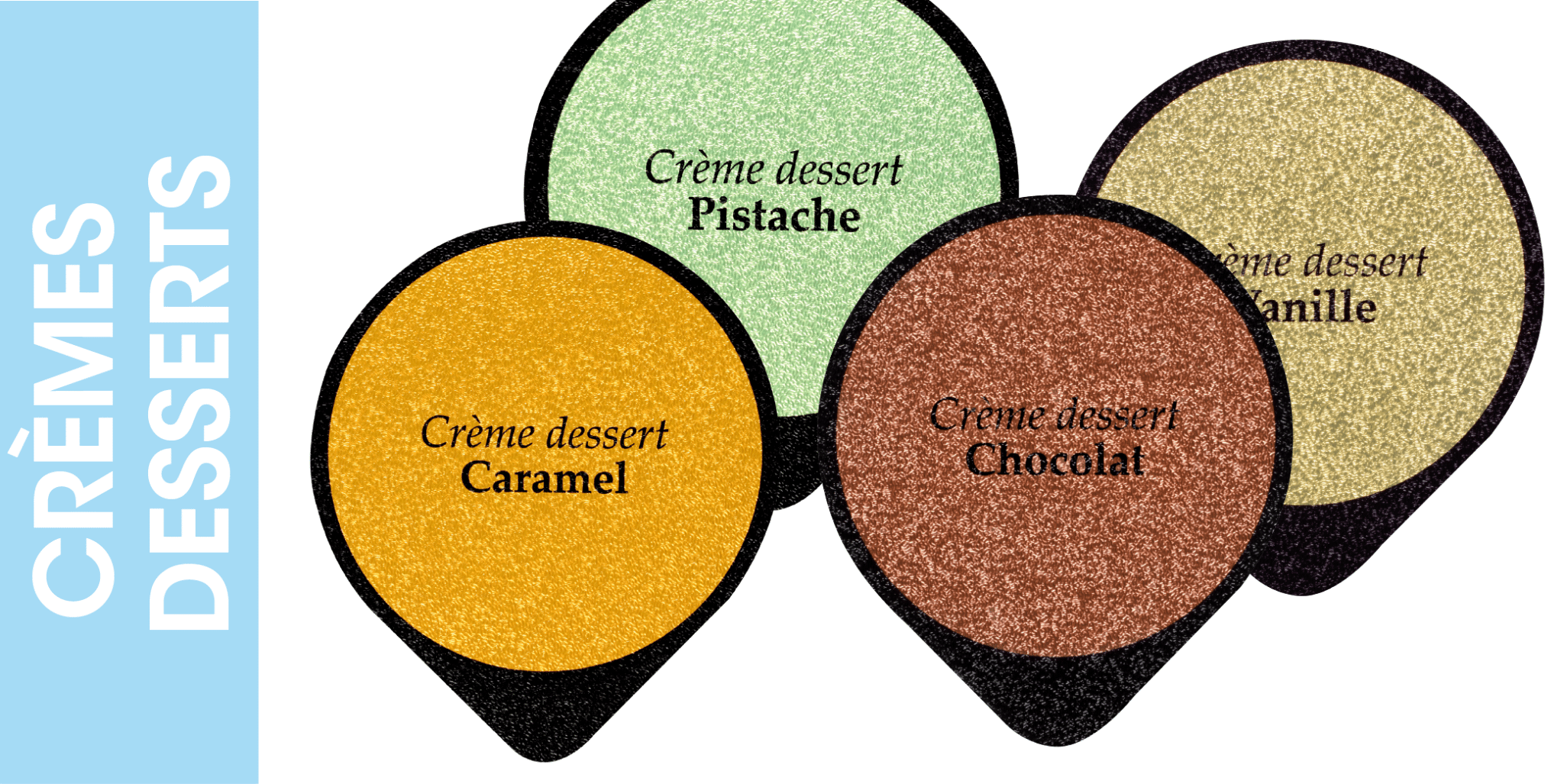

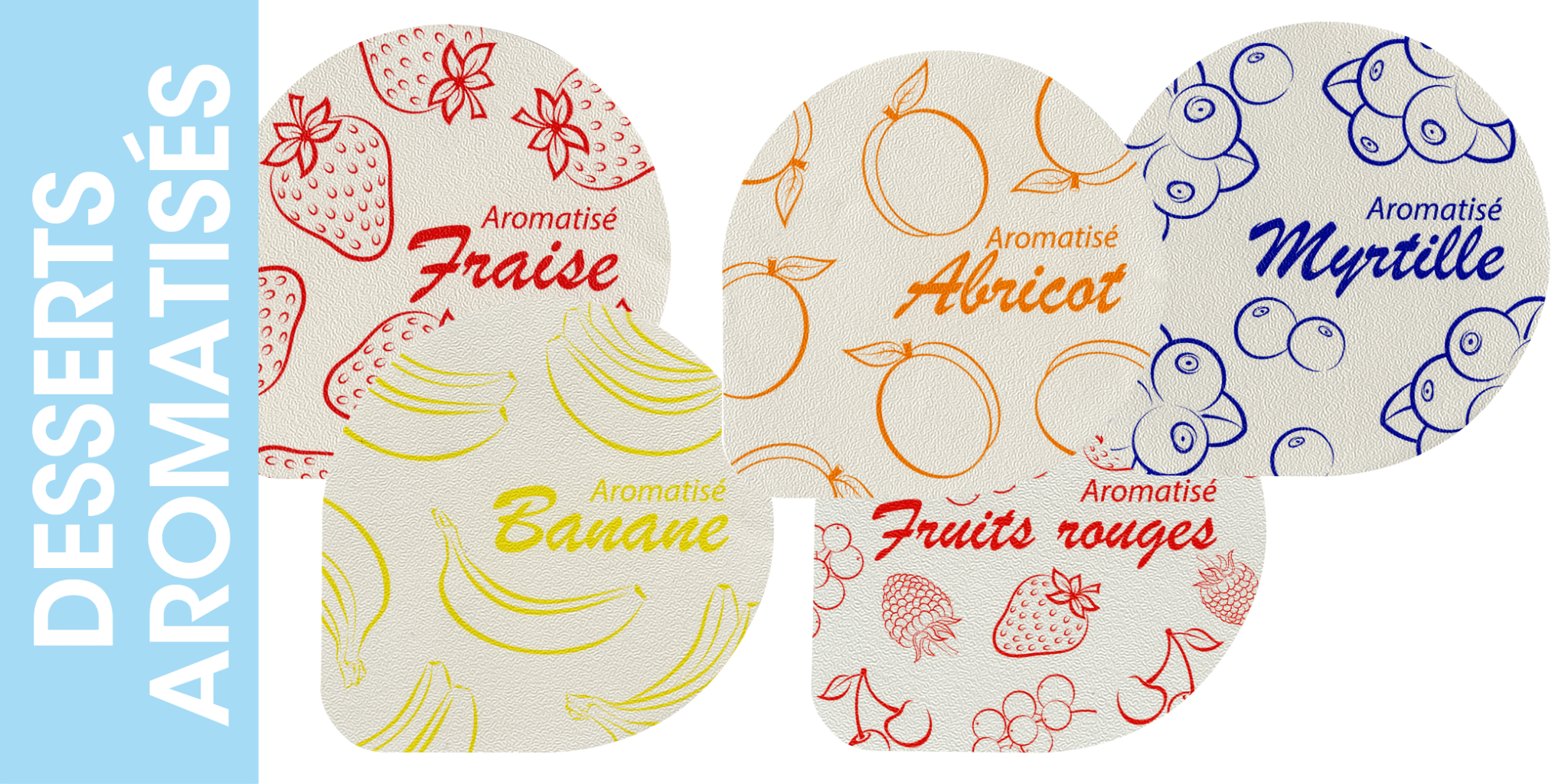

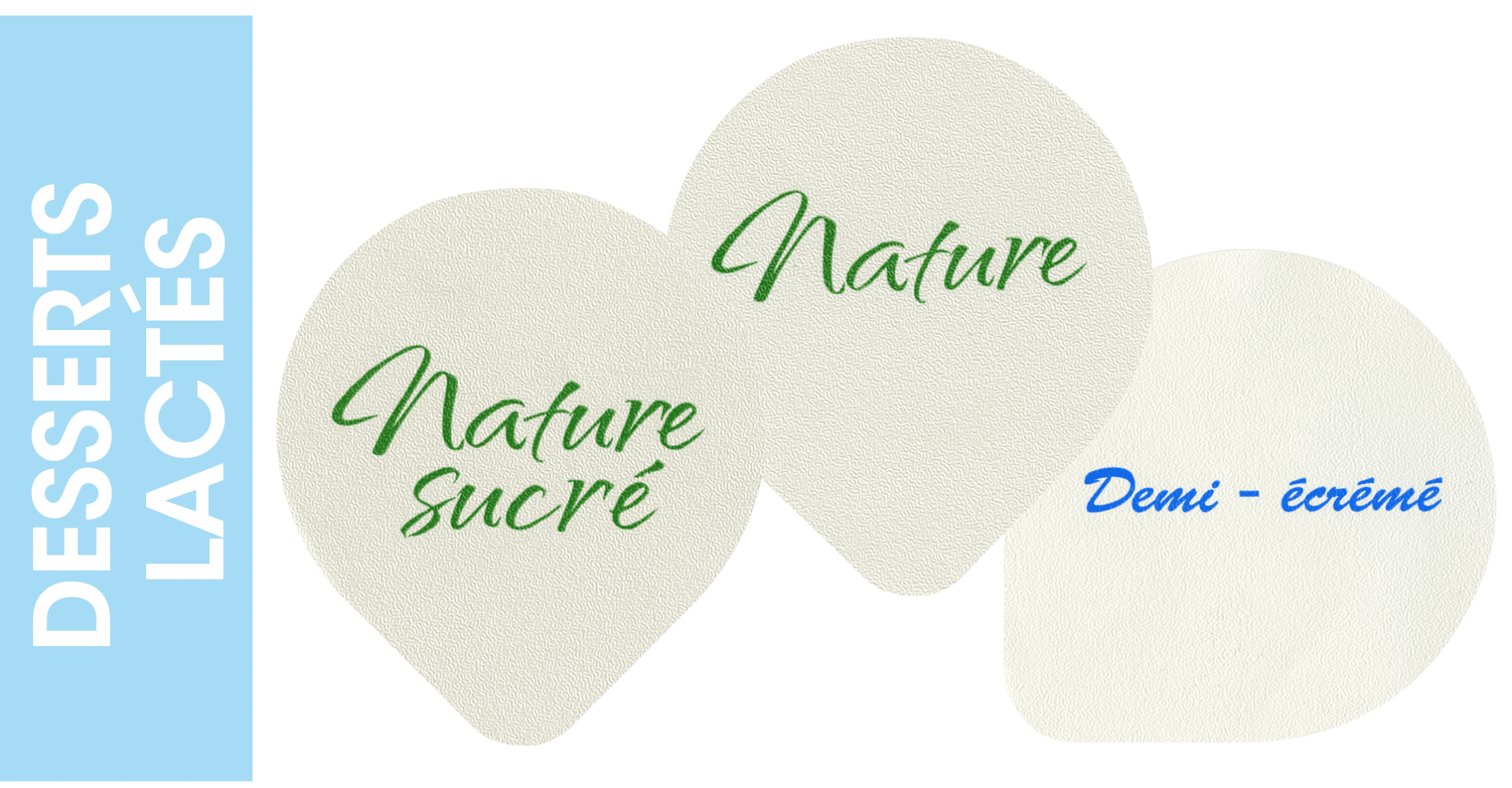

ADAPTED TO YOUR PRODUCTS

Cottage cheese

Fresh cream

Yoghurts

COMPOST

grout

fruit puree

jam

milk

COATING

FERTILISERS

SAND

sauces

mayonnaise

ketchup

PAINTS

LASURES

COLOURANTS

CHEMICAL PRODUCTS

SPICES

TEAS

SEL

CONDIMENTS

Manufacture

100% French

Since 1997, PACKINOV designs and manufactures rotary machines and automatic packaging lines adapted to all products in rigid containers in Beynost (01).

From the outset, this company has opted for the 100% MADE IN FRANCE.

Innovative, top-of-the-range French manufacturer, PACKINOV is present in France and abroad and supports its customers at every stage of their project, in a spirit of partnership. global packaging solution with machines but also pots, the lids and many associated services.

ultra-compact

dosing precision

Non-strippable containers

7000 pots/hour

The RMC 840 heat-seal packaging machine

The RMC 840 heat-sealing machine automatically conditions a wide range of products, whether they are liquids, pastes or solids in non-depilable containers (flasks, jars, bottles, etc.) for the cosmetics, pharmaceutical and agri-food markets.

The RMC 840 packaging machine is highly flexible. It can effectively heat seal different containersWhether in glass, plastic or cardboard.

The RMC 840 heat-sealing machine is high output with a minimal footprint. This machine compact is the ideal choice for companies looking to optimise their production space. With its footprint of approximately 1 m2It can be easily integrated into any work environment.

Format changes are tool-free, quick and easyThis versatility helps you maximise your operational efficiency while meeting changing market needs. This versatility helps you maximise your operational efficiency while responding to changing market needs.

The RMC 840 is a conditioner high-performance, ultra-compact and versatile heat-sealing machinecapable of meeting the challenges of modern production for increase your productivityreduce the space required in your production area, and guarantee the quality of your products, whatever your market.

Designed for

Cosmetic jars

Bottles and flasks

Jars

La RMC 840 packaging machine is

a conditioner ultra-compact multi-format heat sealer

much appreciated for its high cadences and its dosing precision.

Benefits of the RMC 840 heat-seal packaging machine

- Productivity: 7000 pots/h

- Ultra-compact, 1 m2 floor space

- Scalable, in-line, L-shaped or U-shaped positioning conveyors

- High dosing accuracy, up to +/-0.05%

- Suitable for non-depilable containers

- Designed and manufactured in France by 100%

- Easy to clean, CIP, foam cannon, large water volume

- A choice of dispensers for pasty, liquid or solid products

- Ergonomics optimised to suit your constraints

- Food-grade stainless steel, complies with food industry standards

Watch videos of the rmc 840 packaging machine

Reading list

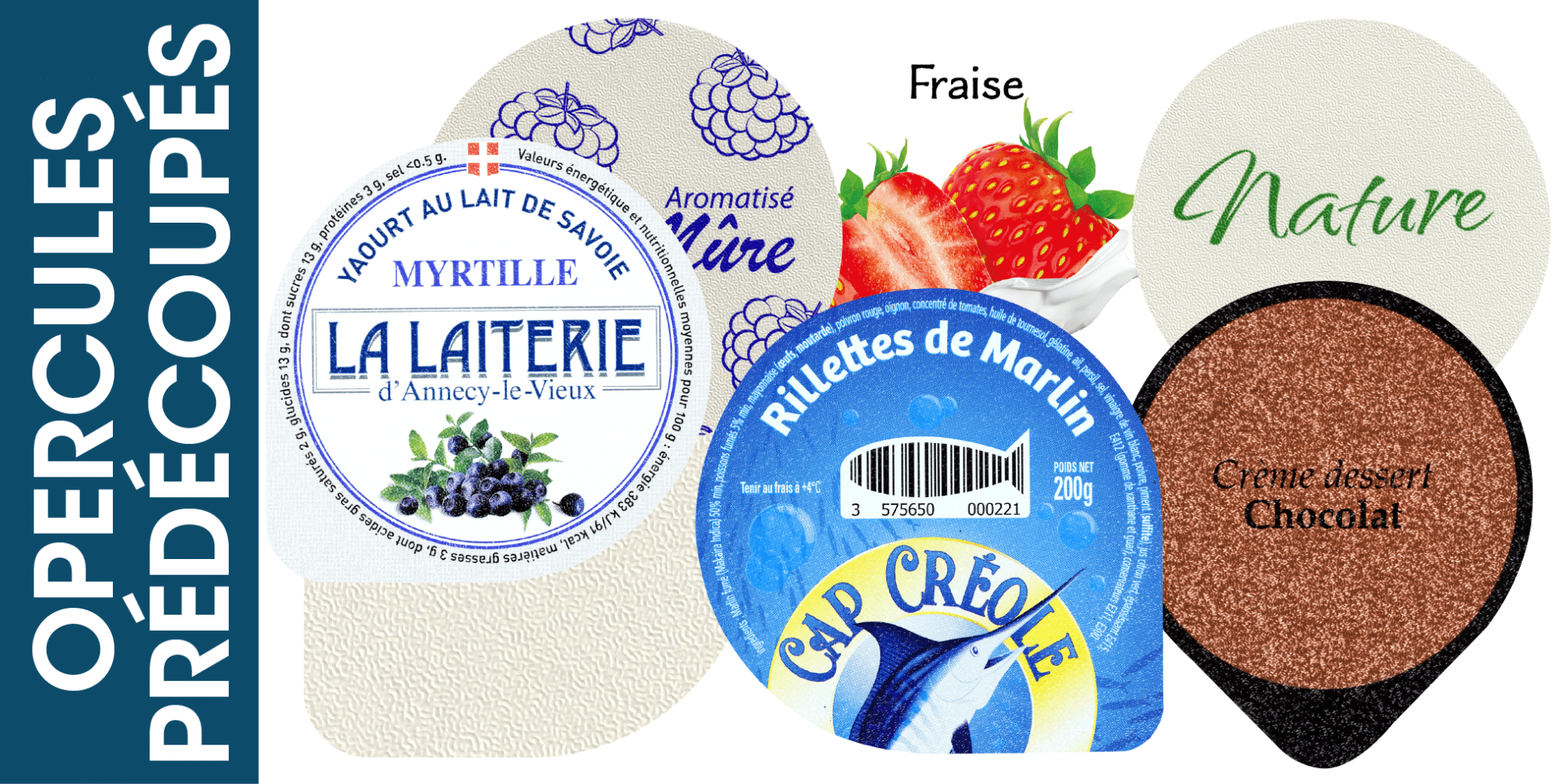

RMC 840 heat-sealing packaging machine suitable for :

to the RMC 840 heat-seal packaging machine

After-sales services

PACKINOV's after-sales service is at your side to maintain, repair and upgrade your module, filler or dispenser.

You can also consult our after-sales guides for routine maintenance of your module.

Pay-as-you-go

PACKINOV will support you throughout the life of your machine and advise you as your production evolves.

Modifications will be carefully studied, proposed to you and then fully handled by our in-house teams, who are fully conversant with the technologies used on PACKINOV machines.

made-to-measure integration

Our teams are available to work with you on the integration of a robot or the LPURE decontamination module into your existing machine.

Our machines are designed by our in-house design office in France, in close collaboration with your teams.

Maintenance

PACKINOV's teams carry out annual maintenance on your module and replace wearing parts to ensure that your machine runs smoothly and your production continues uninterrupted.

Manufacture

100% French

All our machines are developed and manufactured in France.

Discover our production site in pictures.

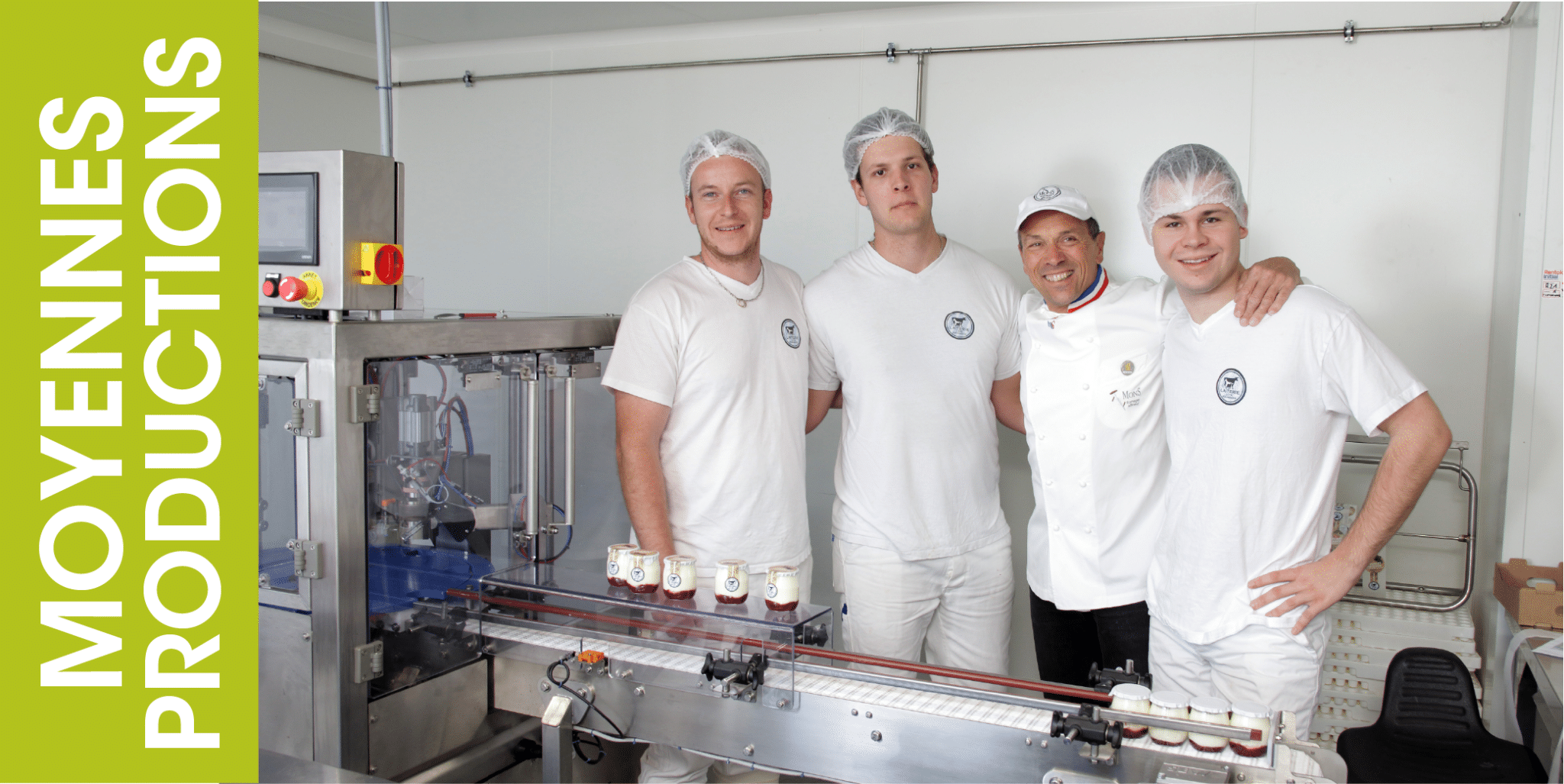

You're delighted

They trust us