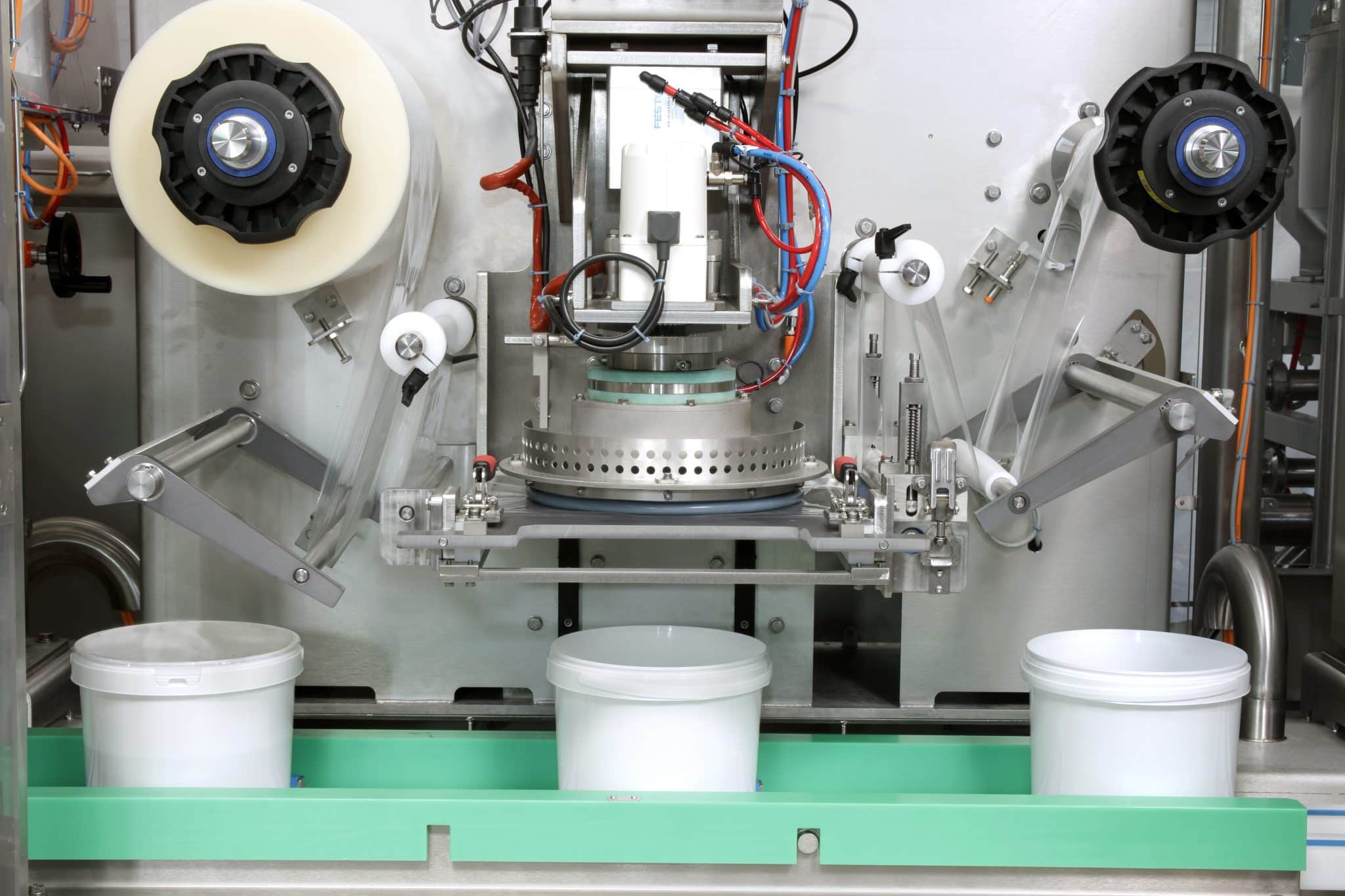

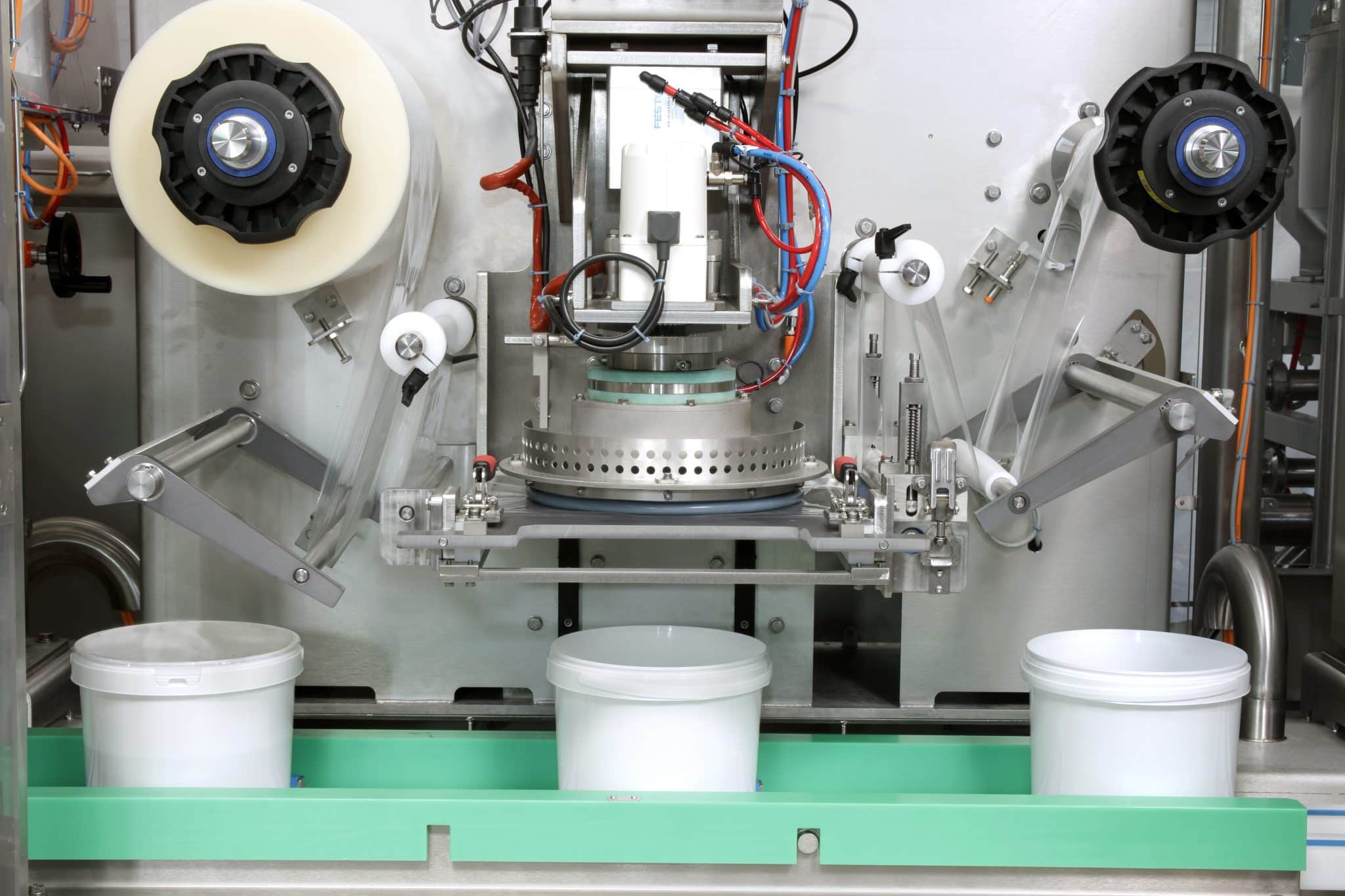

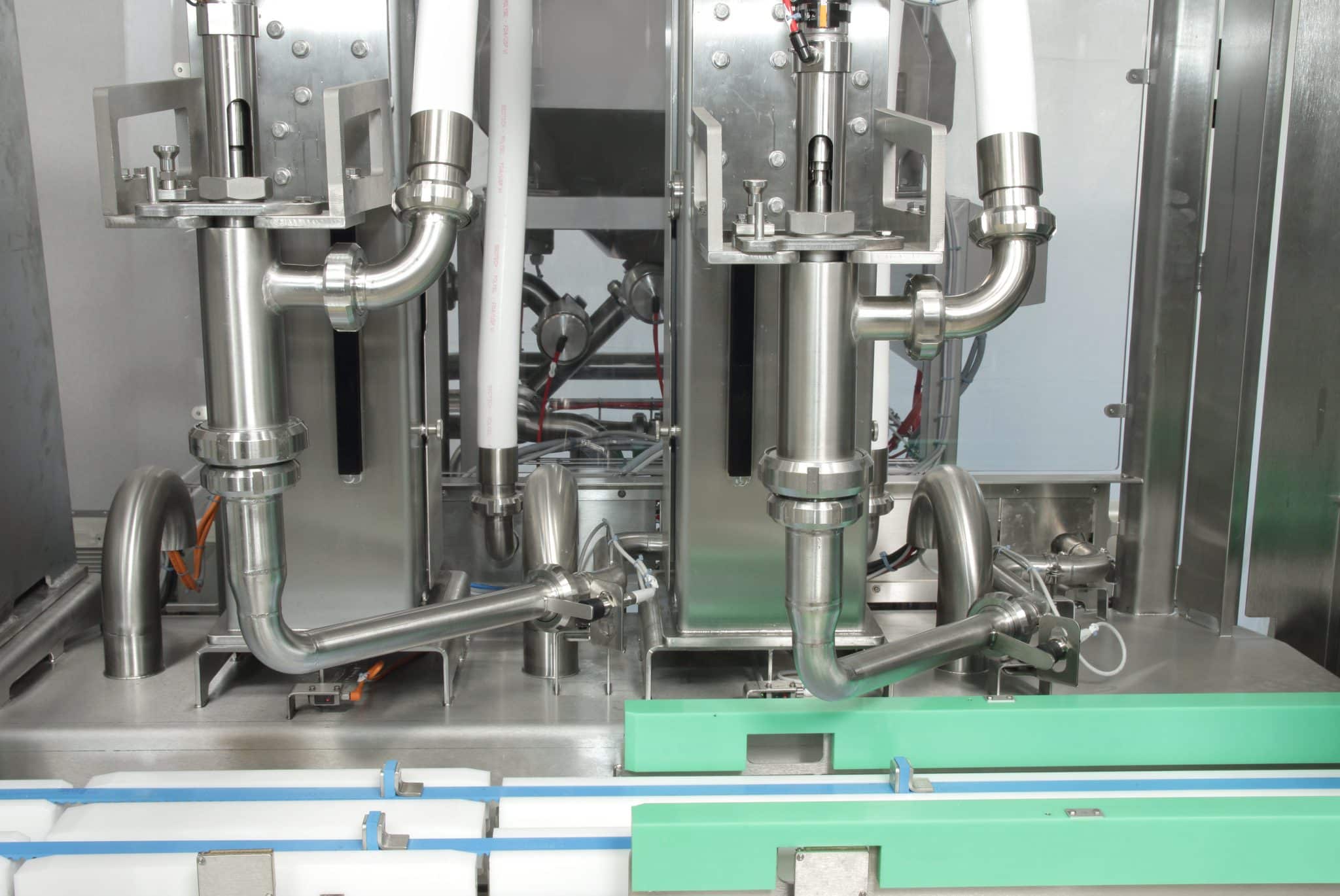

packaging line for buckets

Packaging line for buckets and trays

- High dosing accuracy, product savings

- Perfect dosing consistency, regular production

- Extremely easy to use

- Changing recipes from the touch screen

- Scalable and modular, enabling you to expand your product offering

- High productivity: up to 1000 pots/hour on a single track

- Optimised design and ergonomics based on your layout plan

- Complies with food standards, no intoxication

- Very easy to clean: CIP, large quantities of water, foam cannon, etc.

a reliable and precise packaging line for buckets

In the industrial world packaging machines play a crucial role in ensuring efficiency and flexibility of the production process. Investing in a packaging line PACKINOV, is an essential step in optimising your production process. packaging.

La PACKINOV packaging line for buckets, designed and manufactured in France, is not just a machine - it's a complete solution that meets the constantly changing needs of your business. It offers flexibility unrivalled, enabling your production to adapt quickly to changing market demands. Whether you need to fill liquids, pastes or solids, the PACKINOV packaging machine is up to the challenge.

In addition to its flexibility, the PACKINOV packaging line is designed to offer optimal performance. It guarantees packaging that comply with the strictest hygiene and health standards. This packaging machine also ensures precise vacuuming and inerting, helping to preserve the quality of your products while extending their shelf life.

La PACKINOV packaging line is also progressive. This means it can be upgraded or modified as your specific needs evolve. Whether you want integrate additional functions or adopt new formatsthis packaging machine adapts to your requirements, enabling you to remain competitive in the marketplace.

efficient

buckets/h

high precision

- reliability

La PACKINOV packaging line for buckets is a great reliability for flawless production.

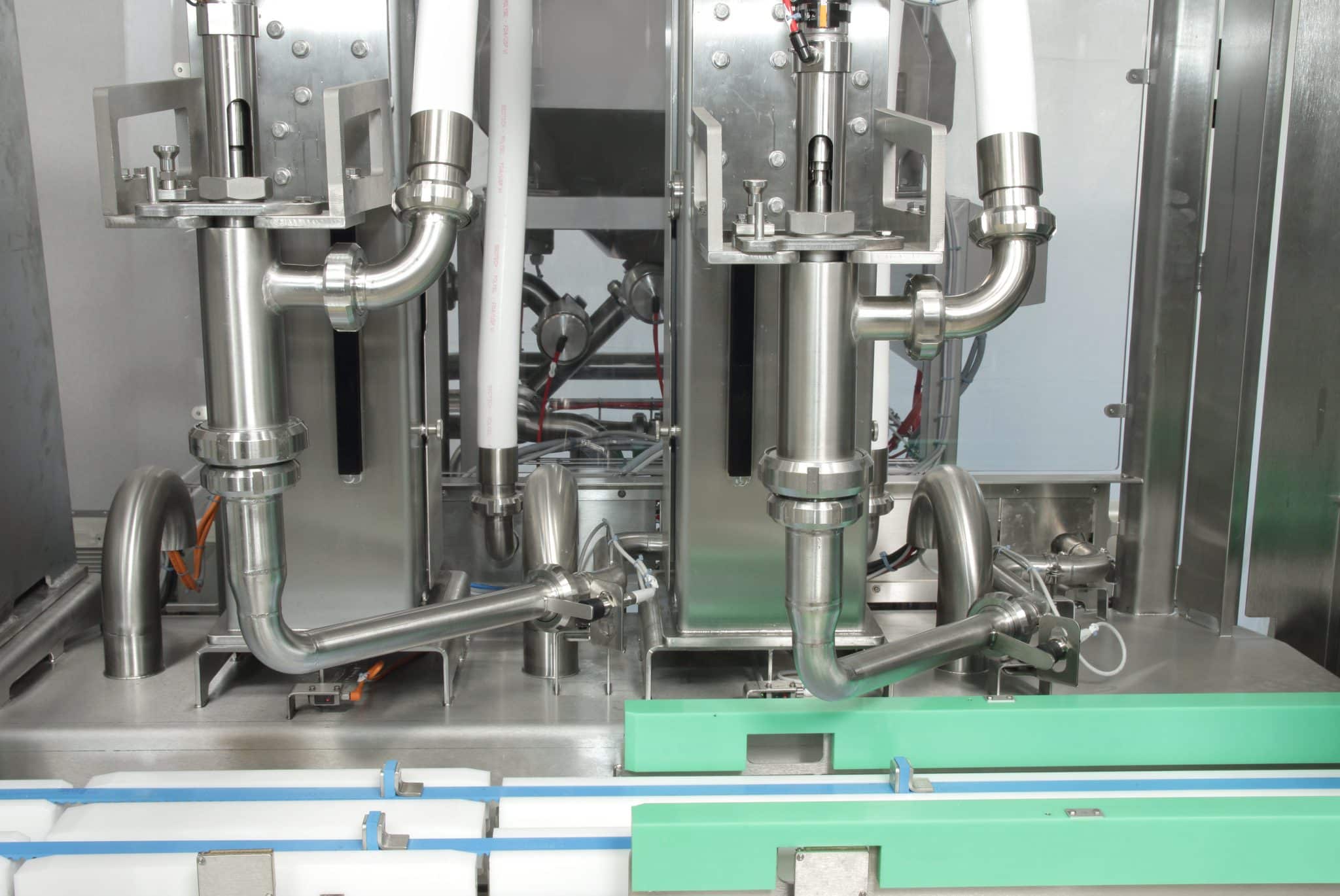

Its precision dosing ensures the right dosage, perfect consistency and real product savings.

- simplicity

Easy to use, the packaging line for buckets has been designed to facilitate production, manage recipes directly from the control console and set the formats to automatic.

It benefits from a easy to clean by CIP, large quantities of water or foam cannon.

- productivity

High performance, PACKINOV packaging line for buckets achieves high speeds on a single track and can produce up to 1,000 buckets/hour.

- scalable and modular

Made to measure in our design office in FranceFrom the outset, the bucket packaging line has been designed to be scalable and modular to adapt easily to changes in your production.

- hygiene and ergonomics

In compliance with your specifications, your layout plan and the recommendations EHEDGthe packaging line for buckets will be custom-designed and developed for optimum ergonomics and hygiene.

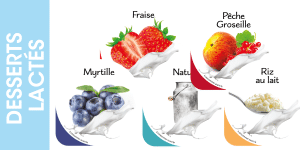

ADAPTED TO YOUR PRODUCTS

Cottage cheese

Fresh cream

Yoghurts

COMPOST

grout

fruit puree

jam

PAINTS

LASURES

COLOURANTS

CHEMICAL PRODUCTS

sauces

mayonnaise

ketchup

COATING

FERTILISERS

SAND

SPICES

TEAS

SEL

condiments

Manufacture

100% French

Since 1997, PACKINOV designs and manufactures rotary machines and automatic packaging lines adapted to all products in rigid containers in Beynost (01).

From the outset, this company has opted for the 100% MADE IN FRANCE.

Innovative, top-of-the-range French manufacturer, PACKINOV is present in France and abroad and supports its customers at every stage of their project, in a spirit of partnership. global packaging solution with machines but also pots, the lids and many associated services.

in-house design

scalable and modular

high precision

1000 buckets/hour

A bucket line for efficient production

The PACKINOV bucket packaging line is the ideal solution for pack all your products in buckets with great precision.

From a perfect regularity and a high dosing accuracyYou'll be able to change formats in record time, guaranteeing unrivalled performance and enabling you to adapt your production line to changing market needs.

The PACKINOV packaging line for buckets is designed to scalable and modular to be able to integrate new functions or adjust the line to other container formats.

The PACKINOV packaging line for buckets is an innovative a versatile, high-performance, scalable solution that will meet your company's requirements while preserving the quality of your products.

Designed for

Square or rectangular buckets

Round buckets

PACKINOV's bucket range offers undeniable advantages

greater reliability on a daily basis and enhanced performance.

The advantages of the PACKINOV bucket range

- Extremely easy to use

- Perfect dosing consistency, regular production

- High dosing accuracy, product savings

- High-performance and reliable

- Multiformats

- Changing recipes from the touch screen

- Scalable and modular, so you can expand your product offering to meet customer expectations

- Automatic adjustment of formats to suit the recipe

- High productivity: up to 1000 pots/hour on a single track

- Optimised design and ergonomics based on your layout plan

- Complies with food standards, no intoxication

- Very easy to clean: CIP, large quantities of water, foam cannon, etc.

Discover the PACKINOV bucket line in videos

Reading list

PACKINOV packaging solutions also mean

to the PACKINOV packaging line

After-sales services

PACKINOV's after-sales service is at your side to maintain, repair and upgrade your machine, filler or dispenser.

You can also consult our after-sales guides for routine maintenance of your machine.

scalable and modular

PACKINOV will support you throughout the life of your machine and advise you as your production evolves.

Modifications will be carefully studied, proposed to you and then fully handled by our in-house teams, who are fully conversant with the technologies used on PACKINOV machines.

MADE-TO-MEASURE DESIGN

Retain all the flexibility you need to tailor 100% production to meet your requirements and specifications.

Our machines are designed by our in-house design office in France, in close collaboration with your teams.

Maintenance

PACKINOV's teams carry out annual maintenance on your machine and replace wearing parts to ensure that your filling machine operates at optimum efficiency and that your production continues uninterrupted.

Manufacture

100% French

All our machines are developed and manufactured in France.

Discover our production site in pictures.

You're delighted

They trust us